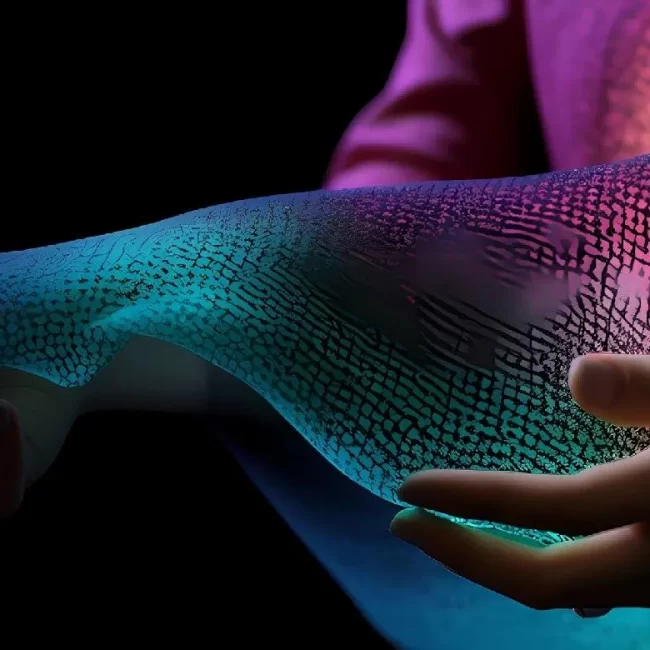

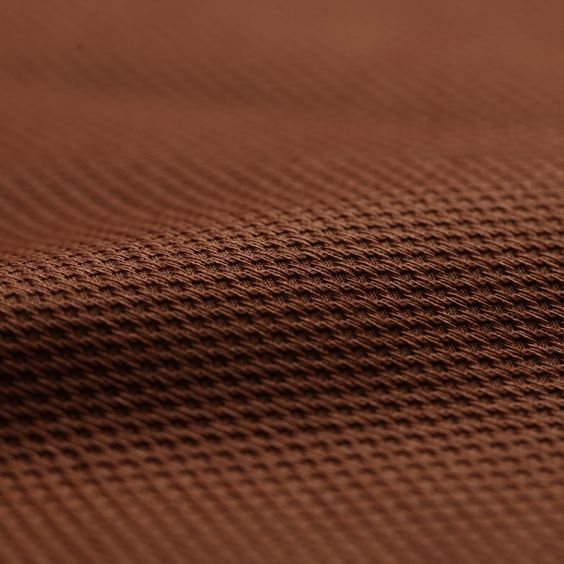

Polyamide Fabric

Polyamide fabric is a general term that is used to refer to a variety of different fabrics that are made from strings of polyamide monomers. The most famous form of polyamide fabric is nylon, but there are quite a few different varieties of this textile.

While these types of fabrics are derived from carbon-based molecules, they are entirely synthetic, which means that they are inherently different from semi-synthetic fabrics, such as rayon, and fully organic fabrics like cotton. Nylon was originally developed by the DuPont Corporation in the mid-1930s as an alternative to silk stockings.

This polyamide was unveiled at the 1939 World’s Fair in New York, and the original marketing material for this fabric insisted that it was stronger than steel and entirely resistant to runs. Therefore, DuPont initially intended to market this new synthetic fabric as “no-run,” but as it became readily apparent that nylon stockings were, in fact, highly susceptible to runs, the name was changed to “nuron” and later “nilon.” Before this fabric entered into mass production, the “i” in “nilon” was replaced with a “y” so that customers would be able to accurately pronounce the name of this fabric.

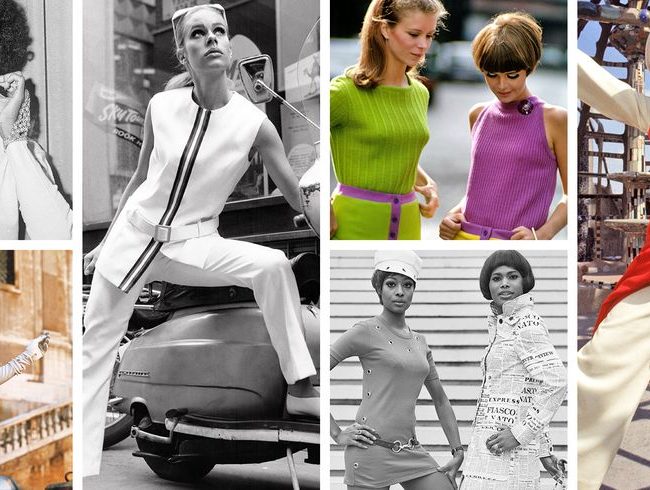

Polyamide fabrics like nylon were commonly used as parachute materials during World War II, and when the war concluded, a shortage of fabrics caused many women to make dresses out of recycled parachutes. As a result, the use of polyamide in women’s apparel became popularized, but pure versions of this polymer were only used in clothing for a short period of time.

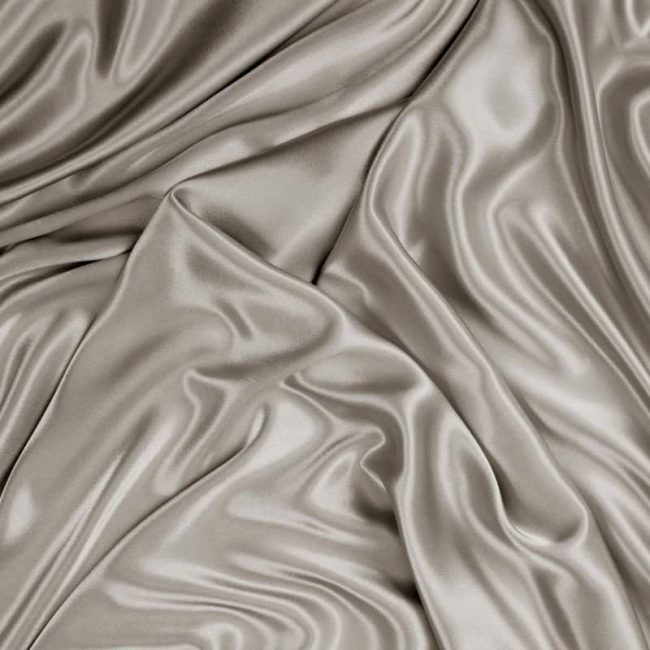

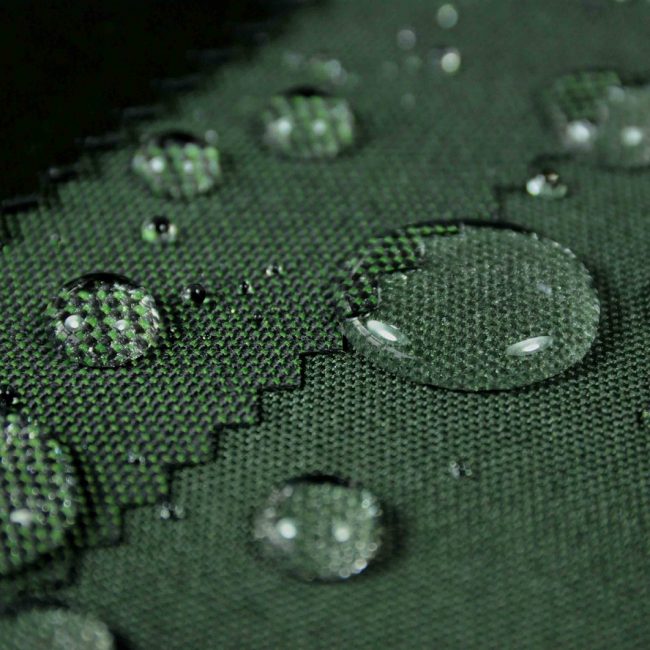

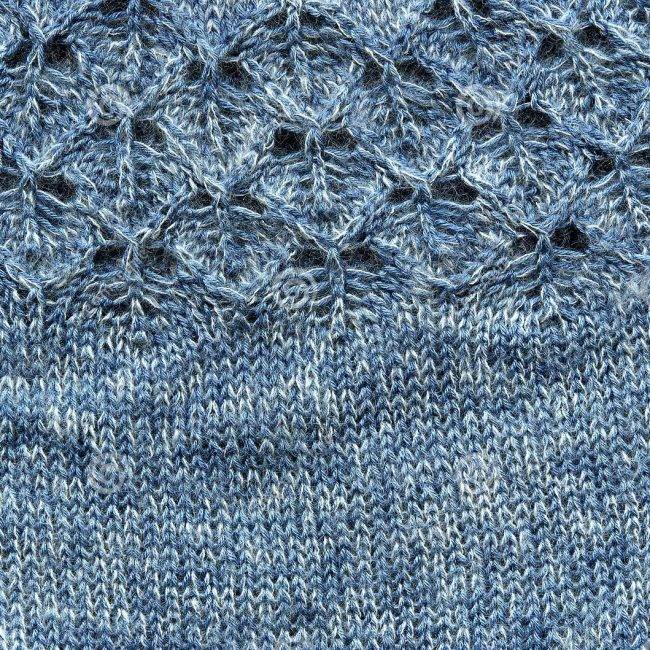

It was quickly recognized by consumers around the world that pure nylon was not well-suited for textile applications. This fabric has a low breathability profile, it is highly subject to damage, and it will melt if exposed to high levels of heat. When blended with other fabrics, however, nylon imparts unique benefits such as elasticity and silkiness, which led to the rise of mixing this fabric with textiles like cotton, polyester, and wool.

By 1945, fully synthetic fabrics represented 25 percent of the global textile market share, but interest in nylon gradually decreased over time. Since polyamide fabrics are usually made with crude oil, the environmental movement of the 1970s put a damper on the production of this textile, and the reduced novelty of fully synthetic fabrics caused consumers to cool on nylon and similar products.

Today, polyamide fabrics represent about 12 percent of global synthetic fiber production, and it’s estimated that this market share will continue to decrease over time. Nevertheless, the unique benefits of this type of fabric continue to accord it an integral place in many types of textiles, and it’s practically guaranteed that production of nylon and other polyamide fabrics will continue unabated throughout the 21st century.

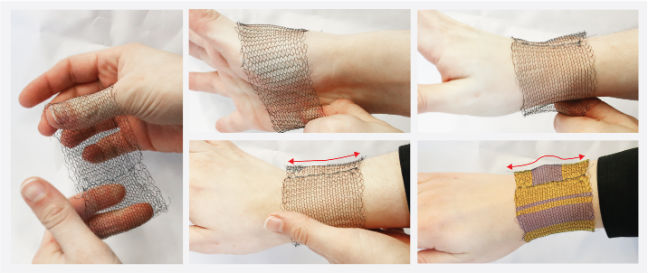

The main benefit of polyamide fabric is its elasticity, and consumers also prize it for its softness. While this textile doesn’t retain heat effectively or wick moisture to the degree that other fabrics do, the ability to shape it into incredibly thin stockings still affords nylon an irreplaceable spot in the global women’s stocking market.

Beyond the world of apparel, nylon and other polyamides have found seemingly permanent homes in scientific and industrial markets. A surprising number of consumer goods are made with polyamides; for instance, many different automotive parts are made with these materials as are toothbrushes, hair combs, firearm components, and various types of food packaging.

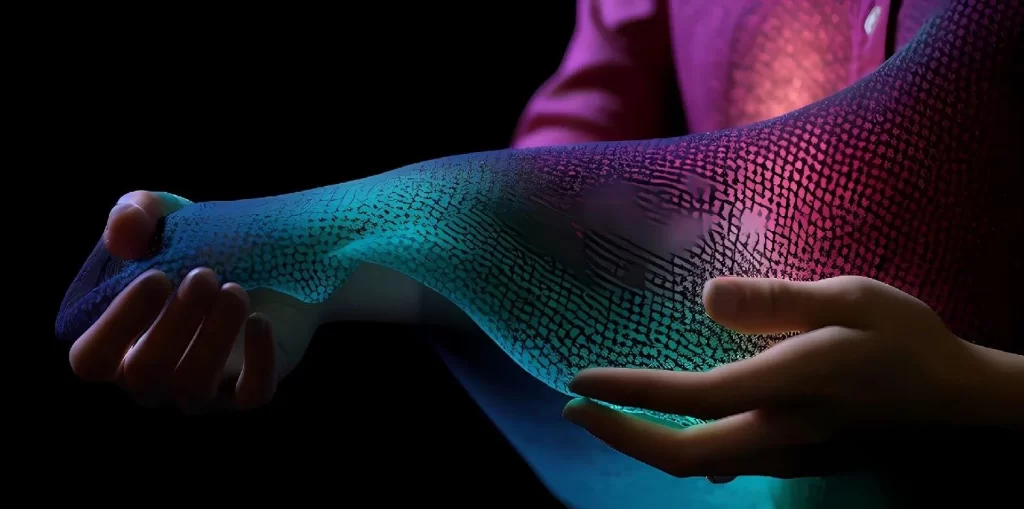

Aramids are other types of polyamide fabric that are commonly in use in a variety of consumer and military applications. Examples of popular aramids include Nomex and Kevlar, and these fabrics are not commonly used in apparel.

Technically, the term “polyamide” can also refer to a variety of organic fabrics such as wool and silk. In the language of chemistry, this term simply refers to a molecule that has repeating amide bonds. However, only chemists refer to silk and wool as polyamides, and the rest of the world considers this term to be synonymous with nylon.

How Is Polyamide Fabric Made?

While the methods used to make polyamide fabrics may vary from manufacturer to manufacturer, they are all alike in being derived from polyamide monomers. In some cases, polyamides may be derived from other sources, but the most common source of these monomers is petroleum oil.

This fossil fuel is also known as crude oil, and it is the base material for a number of different types of plastics and fuel. Petroleum oil is a non-renewable resource, and great lengths are taken to obtain it. Additionally, this base ingredient is inherently a pollutant, which means that the process of producing polyamide fabrics cannot be considered to be environmentally-friendly.

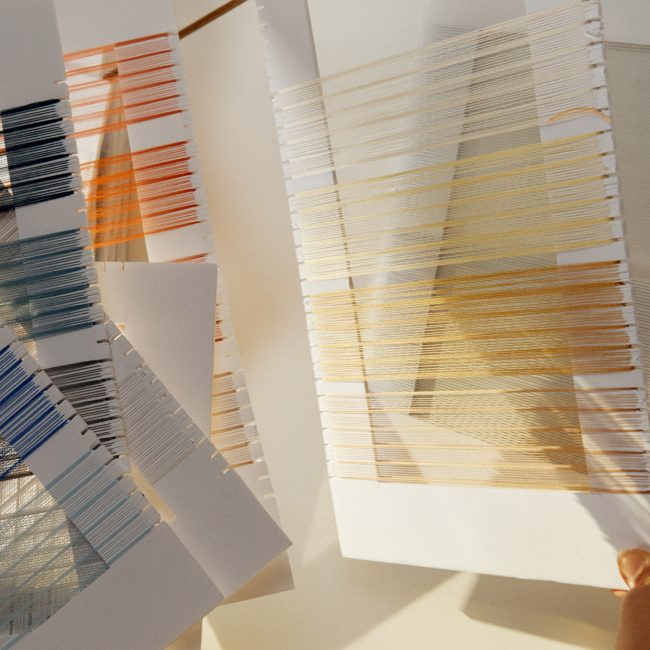

The monomer that is most commonly used in the production of polyamide fabrics is known as hexamethylenediamine, which is also known as diamine acid or just diamine. Nylon 6,6 is the most popular type of polyamide fabric, and this type of nylon is produced when diamine is combined with adipic acid.

A chemical reaction occurs when these two compounds contact each other, and the diamine acid reforms into a repeating chain of monomers that is called a polymer. The polymer known as nylon 6,6 takes the form of a salt, and when this salt is heated, it becomes molten.

Once a polyamide fabric manufacturer has obtained this molten material, it is passed through a metal spinneret with a process called extrusion. The molten polyamide immediately hardens after it is extruded through the spinneret, and it is then loaded onto a type of spool called a bobbin.

During the extrusion process, a large quantity of water is used to cool the molten nylon. Depending on the manufacturer, this contaminated water may or may not be disposed of properly.

After the polyamide fibers are loaded onto bobbins, they are stretched to improve their elasticity and strength. Next, a process called “drawing” is used to arrange the molecules in the polymer fiber in a parallel structure; the fibers are loaded next to each other on a spool, and once this process is complete, the polyamide fiber is ready to be spun into fabric. In most cases, this type of fiber is mixed with other textiles as it is woven into textile products for consumer use.

How Is Polyamide Fabric Used?

When the strict chemical definition of “polyamide” is observed, it can be said that this type of fabric can be used for pretty much any type of consumer textile; after all, silk is used for all sorts of different garments, and many other forms of apparel were made with wool before the advent of synthetic and semi-synthetic fabrics. When the term “polyamide” is limited to synthetic fabrics, such as nylon, the potential applications of this fabric become significantly limited.

Nylon was originally developed as an alternative to silk, and it was specifically offered as another option for women who used silk stockings. Silk is a notoriously finicky substance, and it is time-consuming and expensive to produce. In the end, however, consumers found that pure nylon was inferior to silk, and a variety of other substances were mixed with nylon to make it more durable as a stocking material.

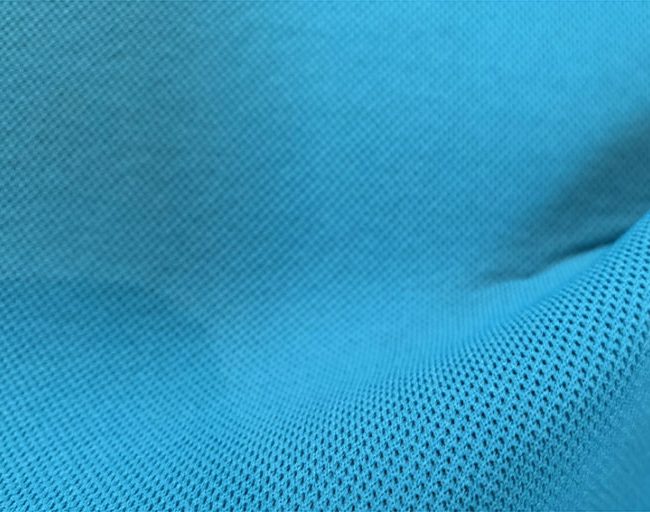

While it’s incredibly rare to find nylon as the only fabric present in consumer textile products, it is often added to apparel and other forms of textiles to improve their elasticity and softness. It’s quite common to find T-shirts, shorts, stretch pants, and a variety of other apparel types that have a nylon content of between 10 and 25 percent. This fabric is particularly popular in underwear, and, of course, it is still used to make women’s stockings even though these accessories are nowhere near as popular as they once were.

It’s important to note that polyamide materials are much more common in non-textile products in contemporary times. Early in the production of nylon, it was found that this type of polyamide forms an excellent type of flexible plastic when it is manufactured with a certain method, and this substance is now found in thousands of types of consumer goods.

Where Is Polyamide Fabric Produced?

Polyamide fabrics were originally innovated in the United States. All of the most common types of nylon, for instance, were created by the DuPont Corporation in the first few decades of the 20th century, and at the time, the development of nylon was considered to be an incredible technological breakthrough.

During the 1970s and 1980s, a large portion of global textile production shifted from the United States to China and other nations in East Asia due to the significantly reduced production costs that international corporations could enjoy in these developing countries. To this day, China remains the world’s biggest producer of polyamide fabrics; for instance, this communist nation produced 1.4 million tons of nylon yarn in 2009.

Overall, nylon continues to represent a smaller and smaller portion of the global fiber production market share. In 1980, more than 10 percent of the textile fiber made around the world was nylon, but this share had shrunk to 5.4 percent by 2009.

While most of the world’s nylon is now made by other countries, DuPont remains the sole producer of Kevlar, and this USA-based corporation has Kevlar manufacturing plants all over the world. In addition, all of the world’s Nomex is also made by DuPont.

How Much Does Polyamide Fabric Cost?

Nylon is generally quite inexpensive; while this fabric was temporarily more expensive than silk when it was first produced, nylon’s cost has now dropped well below the price of this organic material. Kevlar and Nomex, on the other hand, can be quite expensive since they are highly specialized fabrics.

What Different Types of Polyamide Fabric Are There?

Synthetic polyamides can be developed into a number of different fibers, and there are also a few types of naturally occurring polyamides: Some examples of these fabrics include:

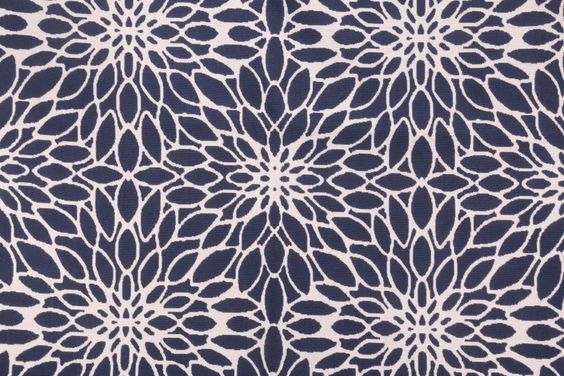

Organic polyamides: Being aware that wool and silk are organic polyamides might impress a chemistry professor, but this knowledge doesn’t have much significance in the world beyond academia. These fabrics are also made from polyamide chains, but they are not synthetic in any way.

Nylon: In most circles, “nylon” and “polyamide fabric” are synonymous, and this polymer is the type of polyamide fabric that is most commonly used in consumer applications.

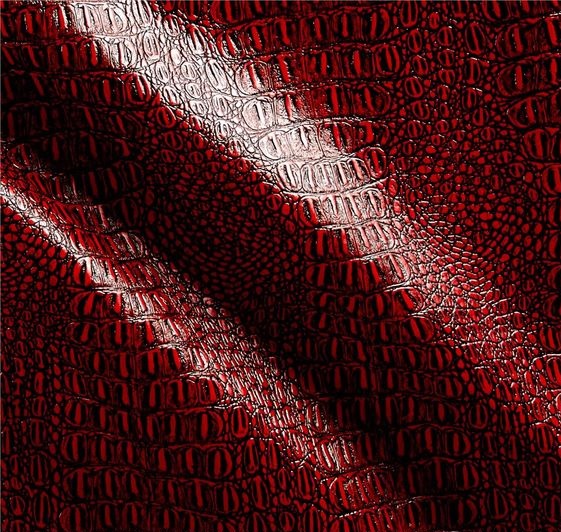

Aramids: While aramids aren’t commonly used in apparel, they are important members of the polyamide fabric. Nomex is a flame-retardant fabric that is commonly used in firefighting gear, and Kevlar is the material used in bullet-proof vests and a number of other applications in which rigidity and durability are desired. Even though these fabrics are also made with polyamide chains, their applications are very different from the common uses for nylon.

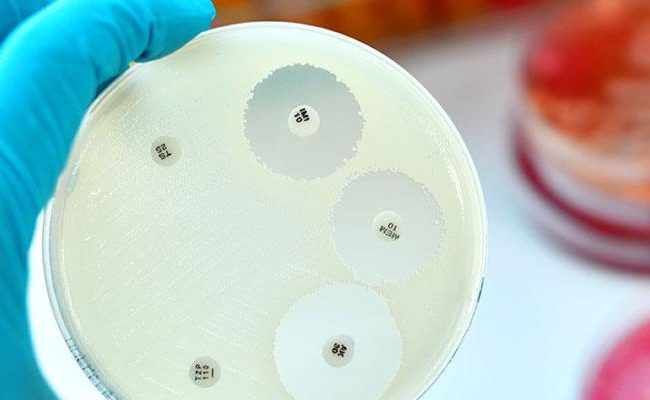

How Does Polyamide Fabric Impact the Environment?

The production of polyamide fabrics generally has a negative impact on the environment. In an era where concerns over the unsustainability of crude oil as a natural resource run rampant, there has been significant pushback against the use of this substance as a base material for fabrics. The international environmental movement has been staunchly against the production of nylon since the 1970s, and while other polyamide fabrics like Nomex and Kevlar are considered to be necessary, nylon’s status as a perceived accessory material has caused it to steadily lose popularity.

Nylon and other polyamides are naturally unsustainable and environmentally degrading, but the production processes that are used to make these fabrics also damage the ecosystem. For instance, the water that is used to cool polyamides often introduces pollutants into the ecosystems surrounding manufacturing plants, and the production of adipic acid, which is used to create most forms of nylon, releases nitrous oxide into the environment.

Nitrous oxide is 300 times worse for the environment than CO2, and nylon and other polyamide fabrics also don’t biodegrade, which means that they are practically permanent pollutants.