What is Elastane Fabric

The scope of the negative impact caused by elastane is debatable. Since the primary components of this fabric are formulated in a lab setting, acquiring the raw materials for elastane isn't considered to be an environmentally degrading process. However, the process of manufacturing this fabric is energy-intensive, and it involves the use of a variety of toxic chemicals.

What Is Elastane Fabric?

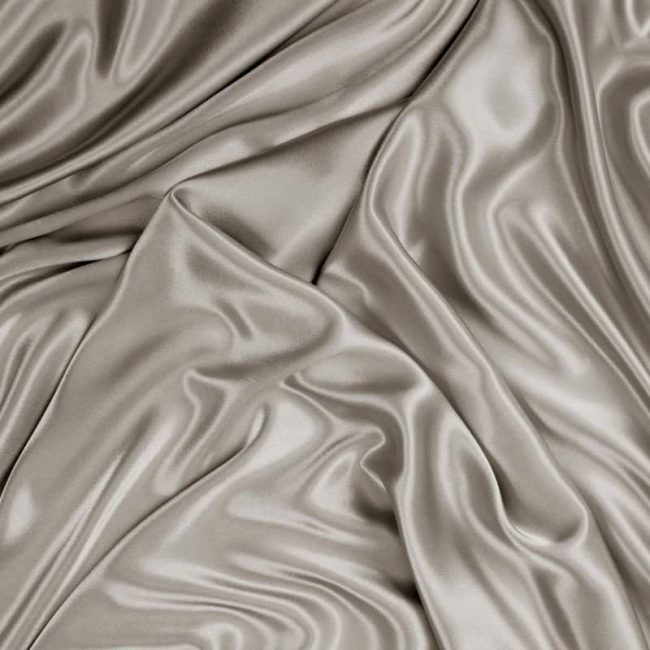

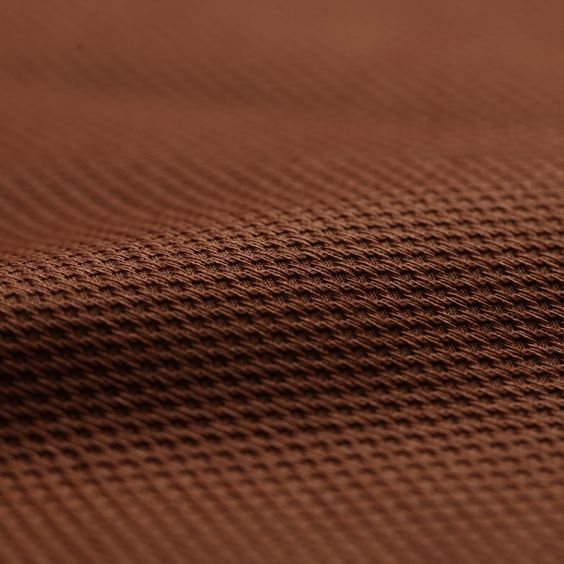

Elastane is the generic term used to describe branded textiles such as Lycra. This type of fabric is also called spandex, and its primary attribute is its incredible elasticity. While Lycra, spandex, and elastane are all the same material, regional variants of the term “elastane” are most commonly used to refer to this type of fabric in continental Europe.

This textile is composed of a long chain polymer known as polyurethane, and it is known in technical circles as a polyether-polyurea copolymer. Elastane is an entirely synthetic fabric; no organic materials are used to make this substance, and it does not exist anywhere in nature.

While elastane was invented in the late 1950s, the story of this material truly begins in 1937 in Nazi Germany. Polyurethane was originally invented by Otto Bayer and his associates at the IG Farben plant at Leverkusen, and this substance was almost immediately made into a variety of plastics. The primary purpose of polyurethane was as a replacement for rubber, which was only available from certain types of trees and, therefore, was subject to unexpected price fluctuations and was sometimes hard to obtain.

The Nazis used polyurethane for coatings on fighter planes, and it was also made into forms of specialty plastics called elastomers. Foam made from polyurethane remains a highly popular shock and heat insulator to this day, and this type of plastic is in wide use in a variety of other applications as well.

At the time, IG Farben didn’t intend to use polyurethane for apparel, but the DuPont Corporation essentially inherited the will of this legendary German company after World War II, and DuPont’s pioneering research into the properties of polyurethane eventually led to the recognition that it could be used to make extraordinarily elastic fabrics.

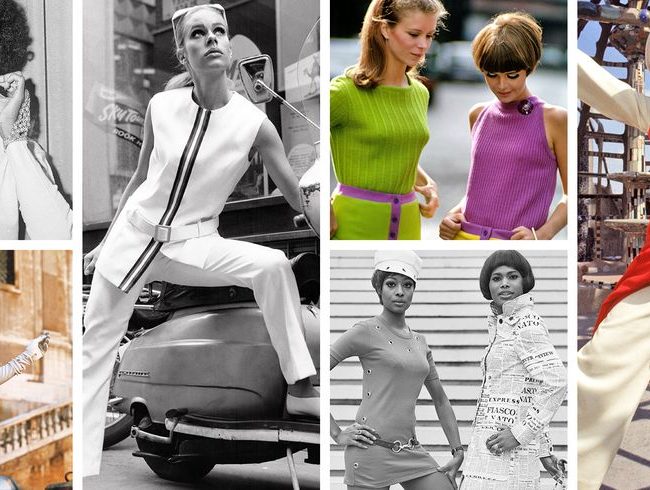

Elastane’s ability to withstand high temperatures was immediately noted by DuPont, and this substance’s stretchiness made it an excellent addition to the various types of polyester that the corporation was currently developing. DuPont branded their elastane under the name “Lycra,” and they immediately began putting it to use in apparel and industrial applications.

This fabric is formed from a variety of different fully synthetic components, and it isn’t considered to have a significantly negative environmental impact. However, a variety of toxic chemicals are used in the production of elastane fabric, and if these chemicals are not disposed of properly, they could damage the environment. In addition, garments made with elastane fabric are not biodegradable.

How Is Elastane Fabric Made?

Four different methods can be used to produce this elastic fabric: Reaction spinning, solution wet spinning, melt extrusion, and solution dry spinning. Most of these production processes have been discarded as inefficient or wasteful, and solution dry spinning is now used to produce approximately 95 percent of the world’s spandex supply.

The solution dry spinning process begins with the production of a prepolymer, which serves as the basis of elastane fabric. This step is accomplished by mixing macroglycol with a diisocyanate monomer within a special type of reaction vessel. When the right conditions are applied, these two chemicals interact with each other to form a prepolymer. The volume ratio between these two substances is critical, and in most cases, a glycol to diisocyanate ratio of 1:2 is used.

When the dry spinning method is used, this prepolymer is then reacted with diamine acid in a process known as chain extension reaction. Next, this solution is diluted with a solvent to make it thinner and easier to handle, and it is then placed inside a fiber production cell.

This cell spins to produce fibers and cure the elastane material. Within this cell, the solution is pushed through a spinneret, which is a device that looks like a showerhead with lots of tiny holes. These holes form the solution into fibers, and these fibers are then heated within a nitrogen and solvent gas solution, which causes a chemical reaction that forms the liquid polymer into solid strands.

The strands are then bundled together as they exit the cylindrical spinning cell with a compressed air device that twists them. These twisted fibers can be made in a variety of thickness options, and every elastane fiber in apparel or other applications is actually made from many tiny strands that have undergone this twisting process.

Next, magnesium stearate or another polymer is used to treat the elastane material as a finishing agent, which prevents the fibers from adhering to each other. Lastly, these fibers are transferred to a spool, and they are then ready to be dyed or woven into fibers.

Since its inception, it has been widely understood that elastane is incredibly useful in a variety of different applications. Unlike other synthetic fabrics, like nylon, this substance isn’t commonly made into plastics, but it is present in many different kinds of consumer apparel. It is important to note, however, that polyurethane, which is the precursor for elastane, is present in a number of different types of consumer, scientific, and industrial plastics.

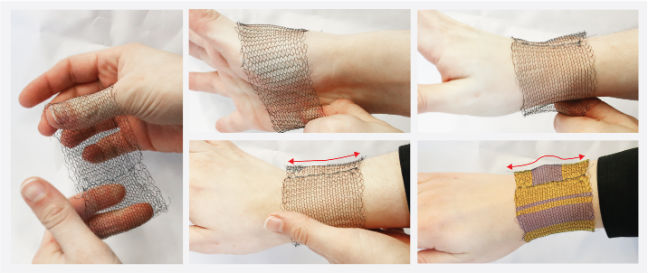

Elastane is used in consumer apparel whenever stretchiness is desired. For instance, this fabric is present in almost every kind of form-fitting underwear for men and women; when this substance is used in undergarments, these garments can be designed on the small side with full knowledge that they will fit to expand the user’s physique when they are worn.

It’s common to see small amounts of elastane fabric used in practically every type of boxer brief, panty, and bra on the market; while this fabric doesn’t make up a large percentage of the end product, enough of it is included to provide stretchiness. If this substance isn’t present anywhere else in underwear, it is almost always present in the waistband.

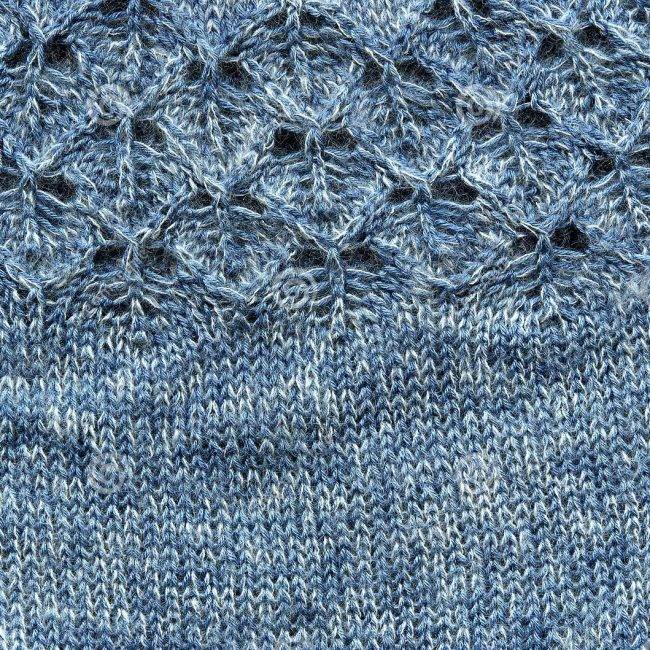

Elastane fabric is also an important component in socks; even socks that are made almost entirely from wool contain at least some amount of spandex to help them stay on a wearer’s feet. Everyday work socks and athletic socks almost always contain 5-10 percent elastane.

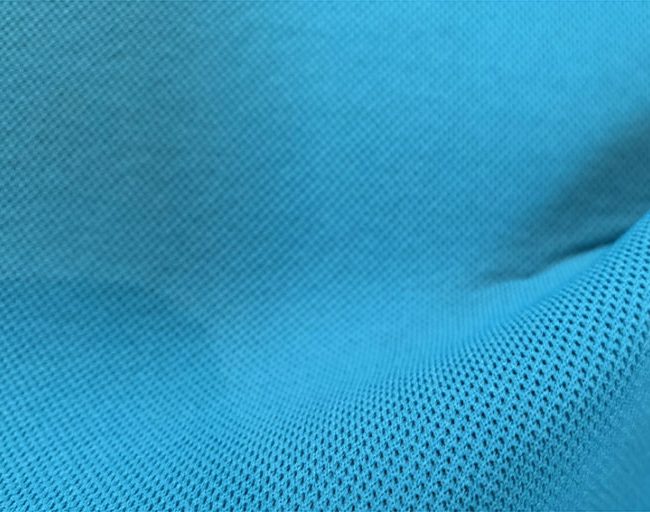

This material is incredibly popular in sportswear of any kind. Whether its yoga pants, bike shorts, swimwear, hiking gear, sports bras, or any other type of garment that is used during intensive physical activity, the form-fitting and elastic benefits of elastane make it an indispensable aspect of this type of garment.

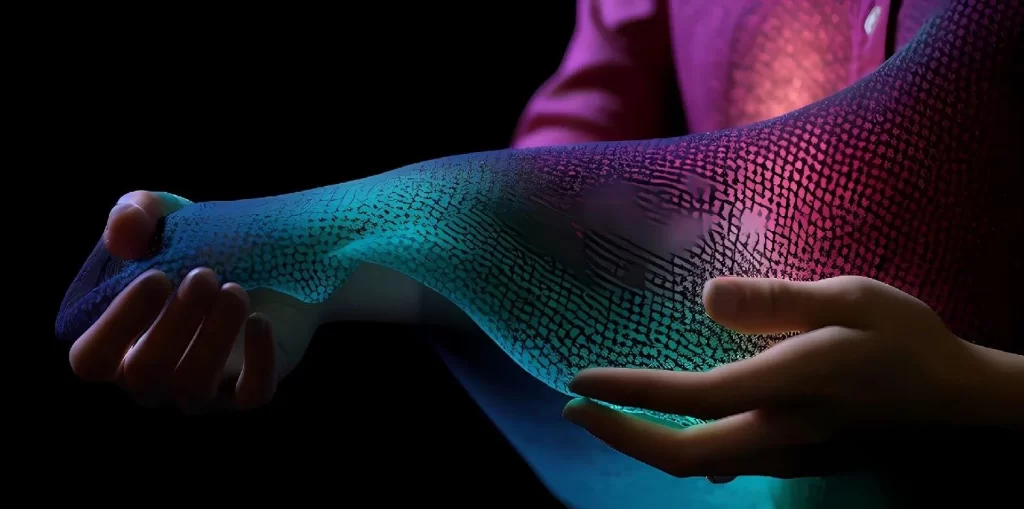

Interestingly, elastane is also an integral part of the motion capture suits that are used in the film industry. Actors wear these suits in front of a green screen, and elastane’s form-fitting attributes make it possible to sculpt 3D appearances on top of the images that are captured while motion capture suits are worn.

Lycra remains the registered trademark of the DuPont Corporation, which means that this company is the only entity in the world market that can produce this form of elastane. However, plenty of other companies around the world make this fabric without trademark restrictions.

Some amount of elastane fabric is still made in the United States, but the vast majority of the global supply of this substance is made overseas. In particular, China controls the greatest market share of this substance, and the global economic report firm ReportBuyer expects that production of elastane worldwide will continue to increase until 2023 and for the foreseeable future beyond this date.

How Much Does Elastane Fabric Cost?

Elastane has an inherently higher value than similar synthetic fabrics, such as polyester and rayon, due to its elasticity. The production process used to make this fabric is also relatively involved, which further raises its price.

Like other textiles, however, the price of elastane is directly affected by market fluctuations; the more elastane there is in supply, the lower its price per yard, and the price inversely raises when there is less of this fabric in supply. At this time, the global supply of elastane fabric is relatively constant, but future market fluctuations could cause unexpected price drops or increases.

Since elastane is still considered to be a novelty material with highly desirable attributes, this fabric is relatively expensive on the consumer end of the equation. Garments that are made primarily from this substance, for instance, are significantly more expensive than garments made from polyester or similar synthetic substances, and they are also often more expensive than garments made from organic fabrics like cotton.

In some cases, these increased consumer prices are due to the comparatively high cost of producing elastane fabric, but under other circumstances, this fabric may be used in niche applications for which inherently higher prices are charged. Professional cycling gear, for instance, fetches a relatively high price due to its perceived prestige, and the same goes for gear for professional ballet performers.

What Different Types of Elastane Fabric Are There?

Technically, there is only one type of elastane, but this fabric is called different names under different circumstances. Some examples of the names used to denote this fabric include:

Elastane: Elastane is the general term used to refer to polyether-polyurea copolymer fabrics. This term is synonymous with spandex, and it can also refer to the substance that DuPont has branded as Lycra.

Spandex: Contrary to popular belief, spandex is not a brand name; it is, in fact, the working title that DuPont gave to their elastane product during its development phase, and the name stuck once the fabric was branded into Lycra and introduced into the consumer market. “Spandex” is an anagram of “expands.”

Lycra: When DuPont began marketing its elastane product to textile manufacturers, they branded it under the name “Lycra,” and this name remains a registered trademark of the DuPont Corporation.

How Does Elastane Fabric Impact the Environment?

The scope of the negative impact caused by elastane is debatable. Since the primary components of this fabric are formulated in a lab setting, acquiring the raw materials for elastane isn’t considered to be an environmentally degrading process. However, the process of manufacturing this fabric is energy-intensive, and it involves the use of a variety of toxic chemicals.

For instance, the production of polyurethane involves the use of carcinogenic chemicals. While it’s unlikely that these chemicals remain present in elastane fabric intended for consumer use, it’s possible that workers who handle this substance during the manufacturing process may be exposed to carcinogens. On the other hand, research has indicated that the increased incidence of cancer related to this workplace exposure is negligible.

Nevertheless, a variety of occupational safety and consumer watchdog organizations have linked isocyanates, which are the raw materials used to make polyurethane, with childhood asthma and other respiratory issues. The presence of isocyanates has been mainly noted in association with polyurethane foam used in furniture, and it is not likely to be present in elastane or related materials.

As long as good manufacturing practices (GMPs) are used during the production of elastane, it is not likely that the manufacture of this product will cause significant environmental impact. The main issue with elastane fabric from an environmental perspective is its biodegradability; fabrics made with this substance do not break down over time in nature, and they gradually accumulate in the environment.

For instance, it’s been found that nearly 60 percent of the trash found in marine environments is composed of non-biodegradable clothing fibers, which means that elastane and similar fabrics contribute significantly to the giant islands of trash that float through the oceans and the debris found in inland waterways. While the beneficial attributes of elastane can’t be replaced with organic, biodegradable fabrics, it’s undeniable that this substance pollutes the environment when it is discarded or even when elastane fibers are plucked from articles of clothing as they are washed.

If an independent agency can determine that elastane fabric is made from entirely recycled components, it may be eligible for Global Recycled Standard (GRS) certification. So far, only one elastane manufacturer has received this certification, but it’s likely that more international manufacturers will rapidly follow suit. Since elastane is a purely synthetic fabric, it is not eligible for non-GMO or organic certification.