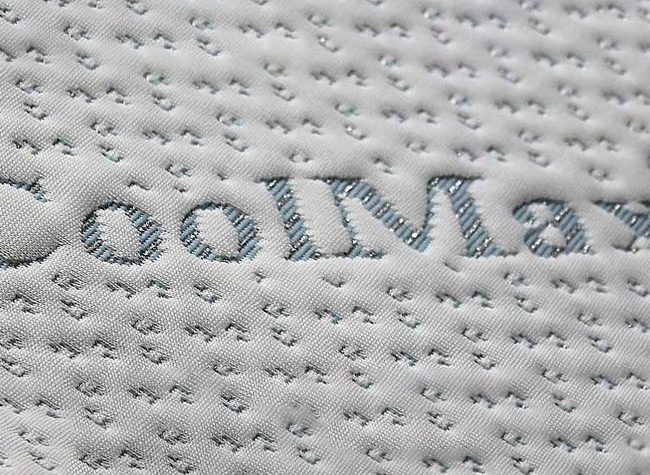

What is OutDry fabric

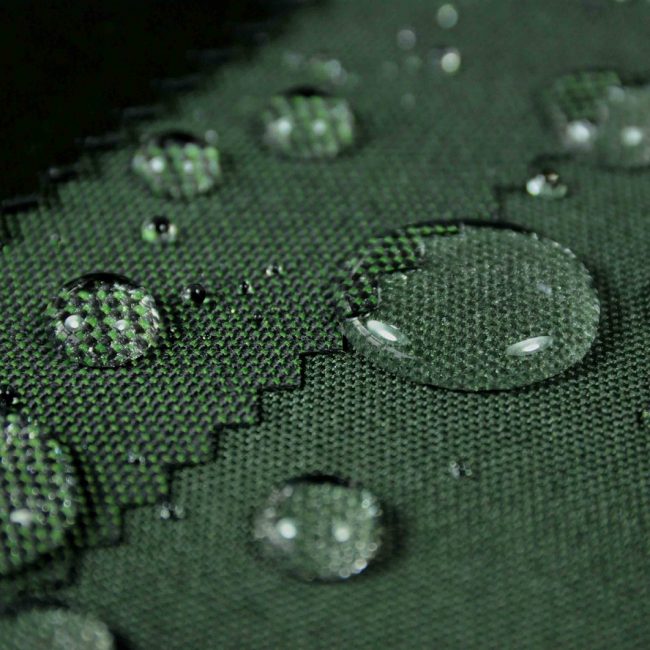

OutDry is a type of waterproof fabric patented and exclusively produced by Columbia Sportswear. As an update to Columbia’s wildly successful Omni-Dry line, OutDry incorporates new technologies that allow waterproofing materials to be melded directly to the outer layers of shoes, jackets, gloves, and other types of outerwear. Previously, waterproofing technologies could not fuse to other materials without the use of unreliable chemicals, resulting in waterlogging and other undesirable drawbacks.

OutDry fabric technical specifications

Columbia has not publicized the chemical properties of its proprietary OutDry material. It is reasonable to assume, however, that the primary material used in OutDry construction is polytetrafluoroethylene (PTFE), more commonly known as Teflon. Every major waterproof fabric since the invention of GORE-TEX has featured Teflon as its base material, so it’s likely that OutDry features a new Teflon formulation that has heat-binding properties.

According to Columbia, OutDry is 100% waterproof, and since this material applies to the outer layer of an outdoor garment or accessory, it prevents water from entering any part of the waterproofed item. Previous waterproofing technologies, especially waterproofing technologies used in footwear, allowed water to pass through the outer layers of the item before being stopped by a waterproof inner lining. Since OutDry prevents water from entering shoes and other items at all, it eliminates the potential of waterlogging, which can make shoes heavy even if their waterproof inner layers remain dry.

History of OutDry

History of OutDry

Founded near Milan, Italy in the early 2000s, OutDry Technologies S.r.l. gained international acclaim upon winning the coveted Ecodesign award at the ISPO 2008 in Munich. The following year, Columbia released a line of gloves through its Mountain Hardwear brand featuring OutDry technology, and in 2010, Columbia announced that it was acquiring OutDry Technologies S.r.l. outright. Outdry Technologies remained headquartered in Italy, but Colombia gained control over the company and began making moves to include OutDry waterproofing technologies in a wide range of products.

By 2013, a variety of Columbia products featured OutDry technology, and in 2016, Columbia announced its first OutDry jacket. The adoption of OutDry in Columbia’s jackets and rain shells essentially spelled the end for the company’s previous waterproofing technology, Omni-Dry. The last Omni-Dry products were produced during Colombia’s 2016 season, and the technology has not been used again since.

Since 2016, Columbia has incorporated OutDry technology into almost all of its outdoor products. Columbia gloves, jackets, backpacks, and shoes designed for wet weather now almost universally feature OutDry technology. Products made by Columbia that do not feature OutDry usually include one of this brand’s alternative technologies, such as Omni-Tech or Omni-Shield. OutDry is considered to be Columbia’s most cutting-edge technology, and this waterproofing material has received overwhelmingly positive accolades from outdoor apparel enthusiasts and critics.

How is OutDry fabric made?

Columbia Sportswear has not disclosed the exact methods used to make OutDry fabric. Basic details regarding what makes OutDry different from competing waterproofing technologies have been released for marketing purposes, however, and assuming that OutDry is made using Teflon, it’s possible to extrapolate some basic information regarding how this fabric is made.

- Production of PTFE

PTFE is a polymer form of tetrafluoroethylene (TFE). To produce TFE, manufacturers combine fluorspar, hydrofluoric acid, and chloroform. These three materials are then subjected to intense heat, resulting in gaseous TFE. Stored under pressure in a low-temperature environment, TFE becomes a liquid, but it remains highly flammable.

To produce PTFE, TFE is exposed to an initiator chemical such as ammonium persulfate or disuccinic acid peroxide and combined with water. Two distinct methods can be used to render TFE into PTFE using water: suspension polymerization and dispersion. With the suspension method, TFE is rendered into small grains or pellets of PTFE, and with the dispersion method, TFE is rendered into a PTFE paste that can be dried and transformed into a powder.

From there, PTFE waterproofing material manufacturers combine this substance with other chemicals to render PTFE into flexible sheets. While the details have not been disclosed, it’s reasonable to assume that OutDry is the result of an innovative process that renders PTFE into a heat-bondable sheet.

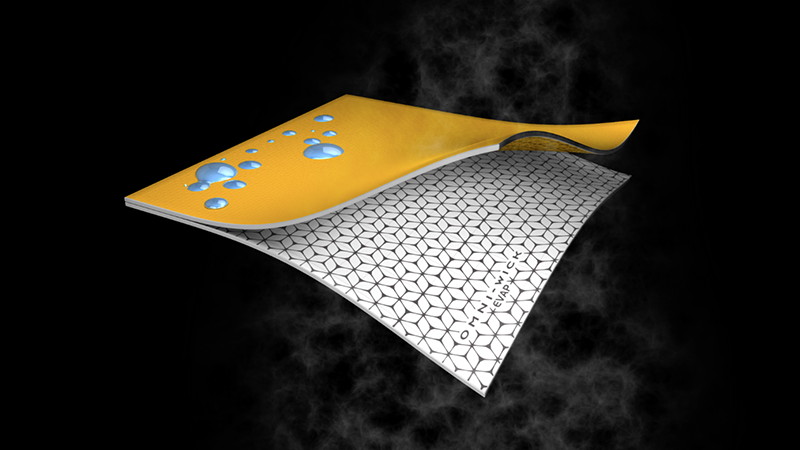

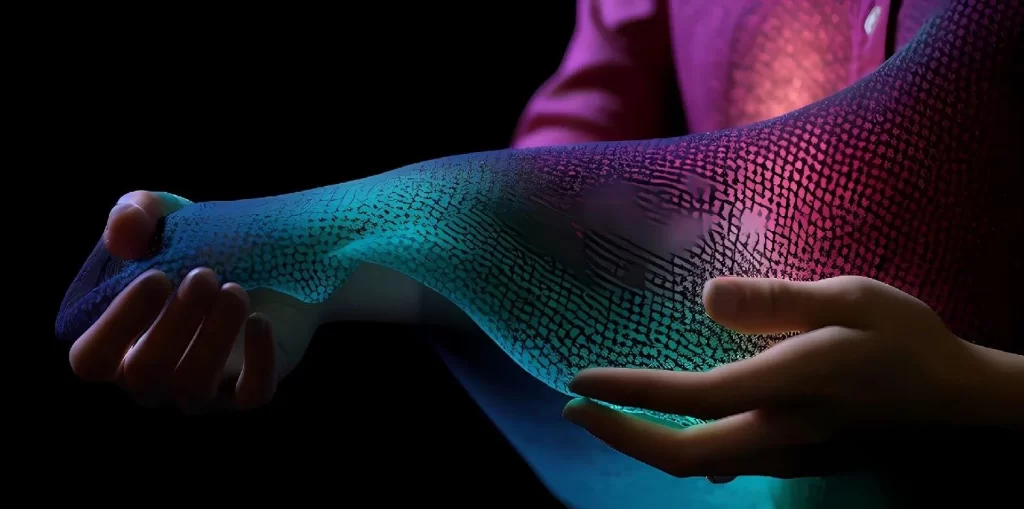

- Cutting to shape and heat application

According to Columbia’s marketing material, OutDry fabric arrives in a sheet that is then cut to match the shape of the product that will be waterproofed. Then, the OutDry fabric is wrapped around the product, and heat is applied to bond the OutDry fabric to the product. The primary advantage of OutDry is that it does not allow moisture to pass through the outermost layer of an outdoor apparel or accessory product.

How is OutDry fabric used?

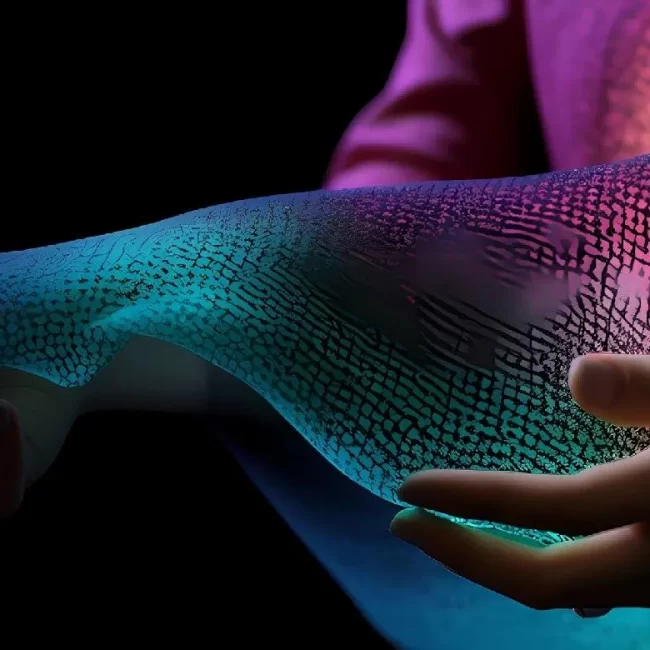

OutDry fabric is used exclusively in Columbia Sportswear outdoor gear. Originally only available in Columbia shoes and gloves, Columbia Sportswear has now diversified its OutDry offerings to include this revolutionary waterproofing fabric in backpacks, jackets, and rain shells. Columbia has also produced a few men’s shirts that feature OutDry, though this application is rare. To provide complete rain protection around your whole body, Columbia offers outdoor pants that feature OutDry waterproofing, and this brand offers at least one line of men’s overalls that include OutDry technology.

Where is OutDry fabric produced?

Like many other American companies, Columbia Sportswear has been moving its production operations out of China over the last few years. While Columbia still makes approximately 60% of its products in China and Vietnam, this prominent outdoor apparel company has also moved some of its production back to the United States. Columbia does not disclose where it produces the majority of its OutDry products, but it is likely that OutDry production is predominantly split between China, Vietnam, and the USA.

How much does OutDry fabric cost?

Columbia Sportswear products featuring OutDry are priced comparatively to other Columbia products. OutDry products also do not appear to fetch significantly higher prices than waterproof products produced by competing outdoor apparel brands. This reasonable pricing indicates that it’s possible to produce OutDry fabric efficiently and inexpensively.

What different types of OutDry fabric are there?

Columbia Sportswear produces a few different types of OutDry fabric, and there are also a variety of competing waterproofing technologies that should be kept distinct from OutDry. Here are a few examples:

- OutDry

Columbia’s basic OutDry technology closely resembles the waterproofing treatment that this company acquired when it bought OutDry Technologies S.r.l. in 2010. Featuring a unique heat-application system and next-generation waterproofing, OutDry is now featured in a variety of Columbia products.

- OutDry Extreme

OutDry Extreme is an updated form of OutDry technology that provides better waterproofing and breathability. Like conventional OutDry fabric, OutDry Extreme offers seamless waterproofing across the entirety of an outdoor garment.

- OutDry Extreme Eco

OutDry Extreme Eco does not feature any intentional perfluorochemicals (PFCs), which are harmful substances that can impact reproductive health and liver functioning. OutDry Extreme Eco is made entirely with recycled materials, and it offers the same benefits as OutDry or OutDry Extreme while saving dozens of liters of water during the production process.

- Omni-Dry

Omni-Dry is a defunct predecessor to OutDry. Prior to Columbia’s acquisition of OutDry Technologies S.r.l., Omni-Dry was this brand’s primary waterproofing technology. Since OutDry utterly outperforms Omni-Dry by every metric, however, Columbia abandoned this technology and now uses OutDry in every application in which Omni-Dry was once used.

- GORE-TEX

Developed in the early 1970s, GORE-TEX is one of the most famous apparel waterproofing materials. With a water column of 28,000mm, GORE-TEX exceeds the 20,000mm water column rating of OutDry fabric. To maintain its waterproofing ability, however, GORE-TEX must be treated regularly with durable water repellent (DWR) coating, which is environmentally harmful and potentially toxic to humans. Additionally, GORE-TEX sometimes allows water seepage through seams in fabric, reducing its utility.

- Omni-Tech

Omni-Tech is an older Columbia Sportswear technology that is primarily used in cold-weather clothing due to its reduced breathability in comparison to OutDry. Featuring a breathable fabric layer with a waterproof layer on top, Omni-Tech is not as efficient or effective as OutDry when it comes to keeping you dry.

- Omni-Heat™

Omni-Heat is a Columbia technology that provides insulation and reflects heat back at the wearer’s body. Primarily used in jackets and pants, Omni-Heat also provides moderate waterproofing, but its main purpose is heat retention.

- Omni-Wick

This Columbia Sportswear technology wicks moisture away from your skin to keep you cool and dry. Since OutDry also features moisture-wicking properties, however, Omni-Wick is now only useful in applications in which waterproofing is not necessary.

- Omni-Shield

Columbia Omni-Shield is a liquid-repellent technology that is not highly breathable. However, Omni-Shield may be more capable than OutDry at preventing stains due to its impressive liquid-absorption resistance.

How does OutDry fabric impact the environment?

OutDry and other PTFE-based waterproofing technologies have a remarkably negative impact on the environment. Even OutDry Extreme Eco, which addresses many of the environmental concerns inherent to OutDry production, remains non-biodegradable and cannot be produced without using harmful, toxic chemicals.

The primary byproducts produced during PTFE production are carbon dioxide and hydrofluoric acid. Exposure to these chemicals, especially hydrofluoric acid, results in a disease called polymer fume fever. As a result, PTFE workers must wear protective gear at all times.

Even if workers are protected from the byproducts of PTFE production, these toxic chemicals still enter the atmosphere and hydrosphere surrounding PTFE production facilities. When it enters soil, PTFE degrades into trifluoroacetate (TFA), which persists in the ecosystem for a long time and harms plant growth.

Products featuring OutDry do not biodegrade, and they are hard to recycle. Since OutDry production only makes up a tiny percentage of global textile manufacturing each year, however, the overall environmental impact of this substance is practically negligible.

OutDry fabric certifications available

OutDry is the sole trademark of Columbia Sportswear, and this material is only available in Columbia products. Therefore, this technology is not eligible for independent certification. Columbia Sportswear does not appear to have solicited independent certification for its family of OutDry technologies.

Pingback: NeoShell Fabric | Fabric | Leather Fabric | KHOSHRANG Co.LTD