Econyl Fabric

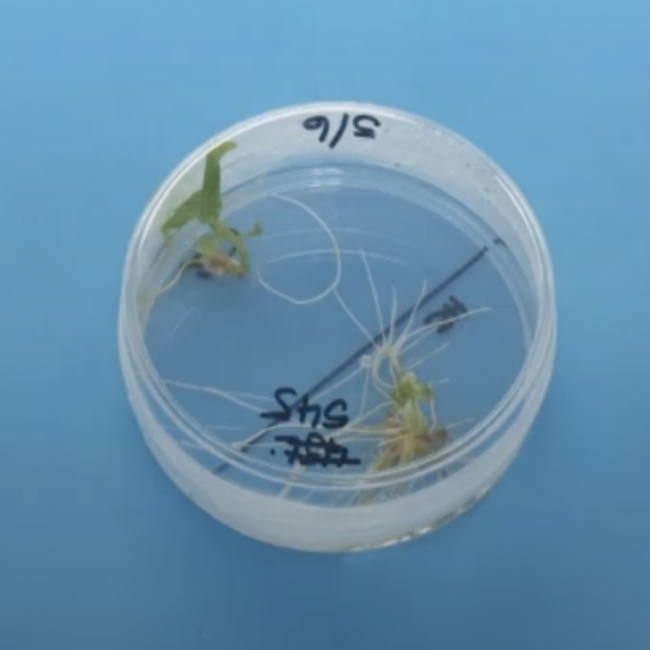

Econyl is an alternative to nylon made from waste products. Normally, nylon has a significantly detrimental environmental impact, but the creators of Econyl seek to help reduce the effects of this fabric on the environment by using recycled base materials.

Econyl History

Econyl is a trademark of the Italian plastics company Aquafil. This company has also produced a variety of other textiles and industrial plastics, but it is most well-known for developing Econyl fabric. Inspired by the environmental crisis caused by synthetic fibers, the creators of Econyl sought to devise an alternative to nylon that doesn’t harm ecosystems.

Nets are one of the most common industrial applications of nylon, and this fiber is also used in a variety of other maritime applications. Additionally, much of the nylon waste that consumers discard ends up in the ocean. This non-biodegradable nylon waste harms sea turtles, dolphins, and other aquatic creatures, and it gradually builds up until it creates islands of plastic that grow year by year.

Nevertheless, the consumer demand for nylon continues unabated, and at some point, Aquafil, which was already an established synthetic textile producer in Italy, recognized the profit potential that all the nylon waste in the oceans posed. Starting in 2010 or 2011, Aquafil started looking into the idea of producing an environmentally sustainable alternative to nylon using aquatic nylon waste material, and production of this new textile fiber began in late 2011.

The story of Econyl is built on the history of nylon. This textile was originally produced by the American DuPont Corporation in the early 1920s, but it didn’t enter into high-volume production until the beginning of World War II. During the war, materials for parachutes and other textile-based war materiel were scarce, and domestic producers turned to synthetic alternatives to silk, cotton, and other natural fibers. By 1945, nylon and other synthetic textiles commanded over 25 percent of the textile market in the USA.

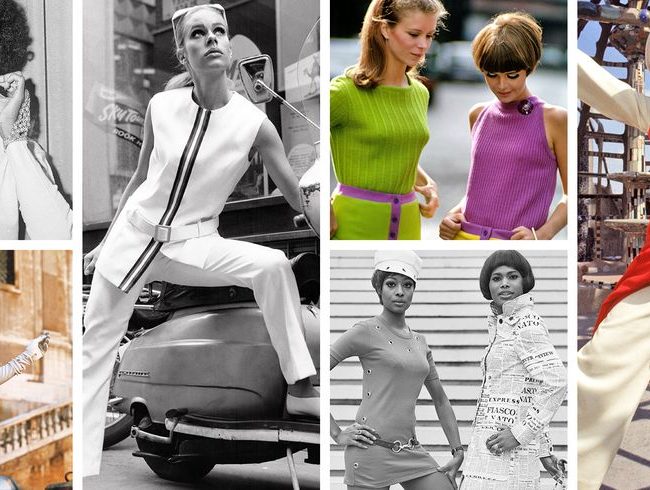

During the postwar era, nylon became popular as an alternative to silk for stockings, and other applications of this stretchy, abrasion-resistant textile were rapidly discovered. Over time, however, consumers recognized that the marketing hype surrounding nylon was largely unfounded; far from being “stronger than steel,” nylon was relatively easy to tear, and this fabric’s flammability quickly became cause for concern. Early forms of nylon would occasionally even revert to coal and water with limited heat application.

With the birth of the environmental movement in the 1970s, public blowback against synthetic fabrics reached a fever pitch. While this antagonistic consumer attitude toward nylon and other synthetic fabrics has lost its shrillness over the years, consumers remain disenchanted toward synthetic fibers, and this dissatisfaction with existing synthetic fiber options eventually led to the market demand that precipitated the development of Econyl.

Econyl Attributes

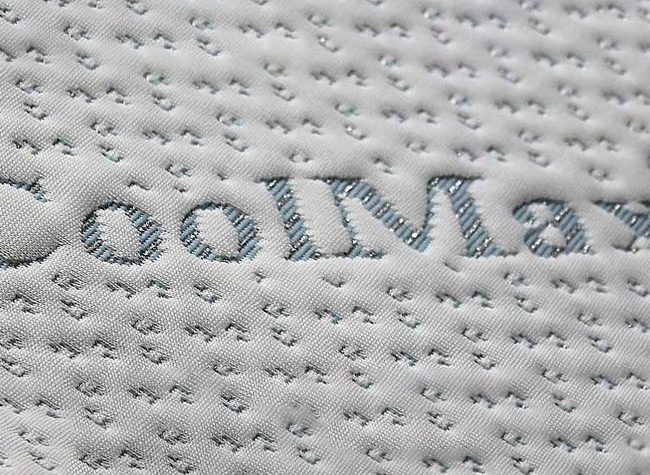

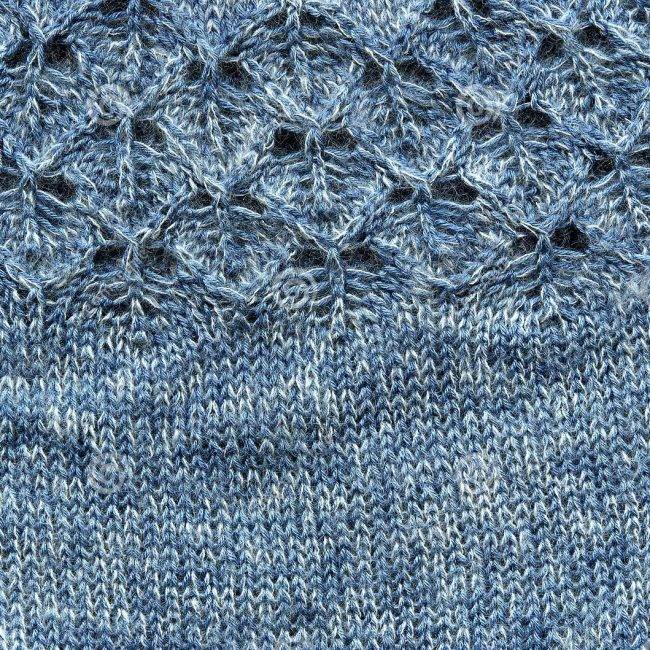

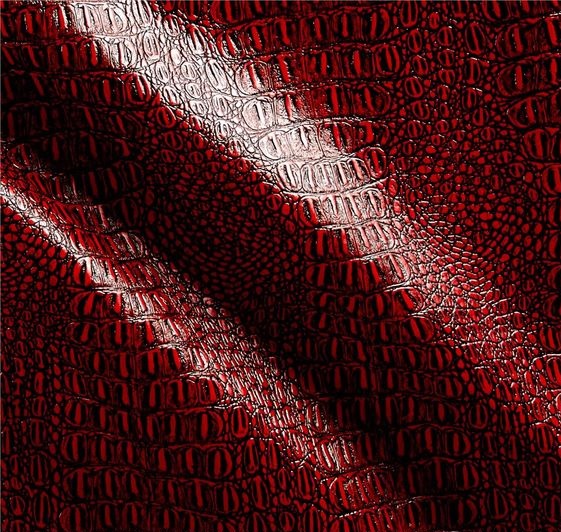

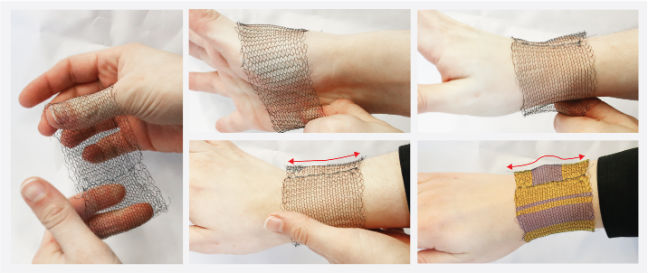

Since Econyl is chemically identical to nylon 6, it has all the attributes of normal nylon fabric. This fiber is stretchy when woven, relatively tough, and easy to weave into tightly-knit garments and industrial textiles.

Since Econyl’s main desirable attribute is its elasticity, consumers are largely unconcerned that this textile is not incredibly heat-retentive or durable. It’s important to point out, however, that nylon and Econyl are not elastic in their raw form; these fibers must be woven into fabric to become stretchy.

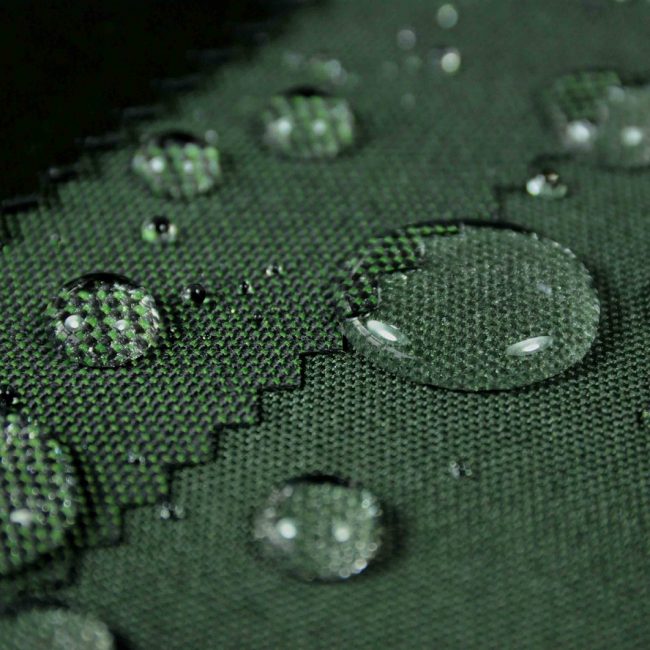

Therefore, the inherent rigidity of Econyl makes it ideal for non-apparel applications. However, this fiber is highly flammable, and it melts when ignited, which poses injury risks to workers. Econyl is not moisture-wicking, and it will melt if washed at high temperatures.

How Is Econyl Fabric Made?

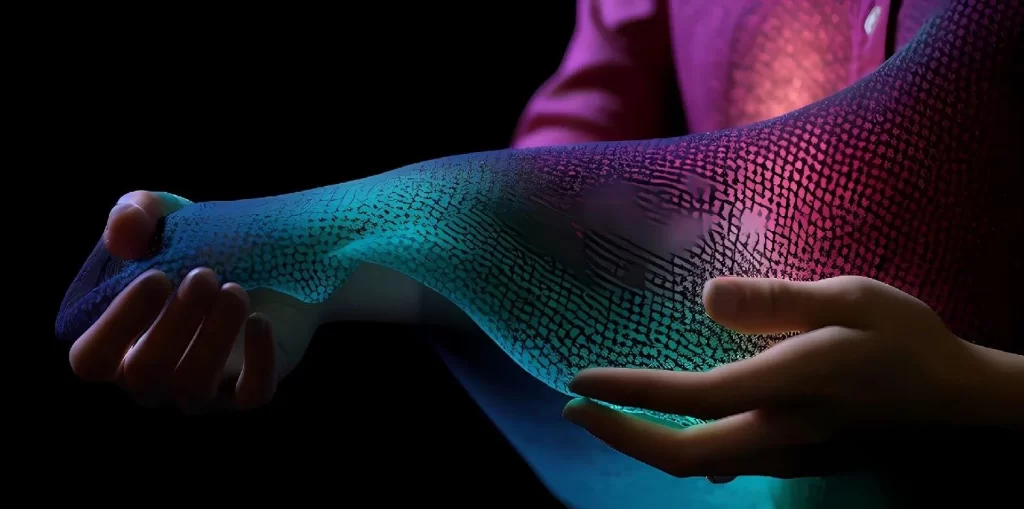

Aquafil has not disclosed the exact processes it uses to make Econyl. The only information available details a vague process of capturing nylon waste, subjecting it to depolymerization, and reconstitution of the resulting material into nylon yarn.

Since this process does not involve the production of nylon polymer, no fossil fuel base materials are required. However, the fact that “depolymerization” is an aspect of Econyl production indicates that chemical processes are used to break down existing nylon polymer into a monomer state before it is reconstituted into a polymer.

Apparently, this process is undertaken to remove any impurities from existing nylon fiber, and it’s unclear whether the production of Econyl involves reacting diamine acid with adipic acid as is the case in normal nylon production. It’s likely, however, that the constituents of the recycled nylon are rendered down into a molten polymer state, extruded through spinnerets, drawn, and loaded onto bobbins.

From this stage, the Econyl fiber can be spun into yarn, treated with chemicals, and dyed. It is then ready to be woven into consumer apparel.

How Is Econyl Fabric Used?

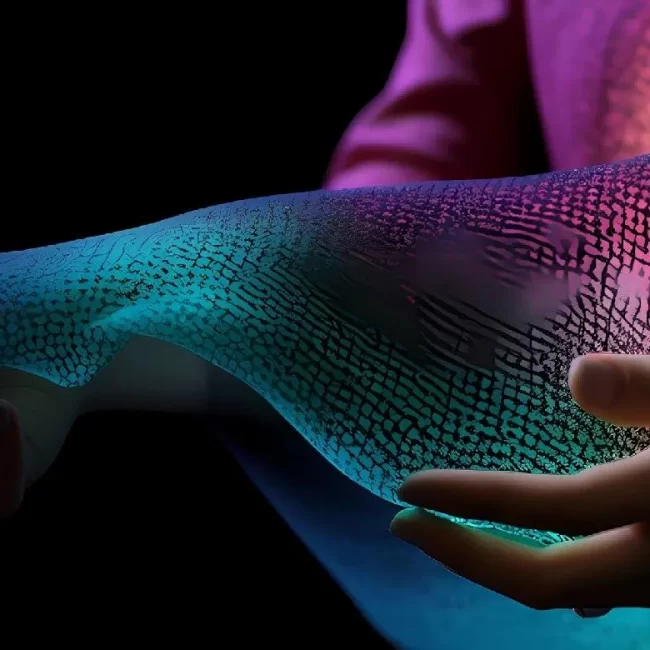

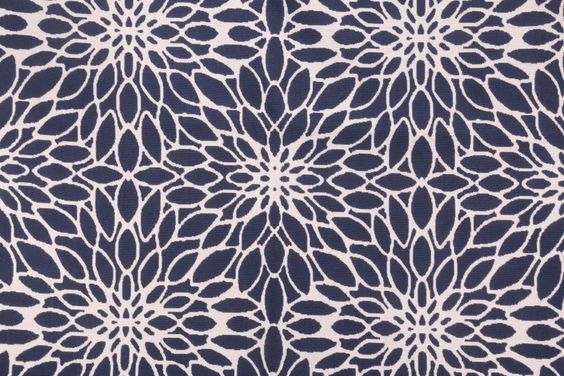

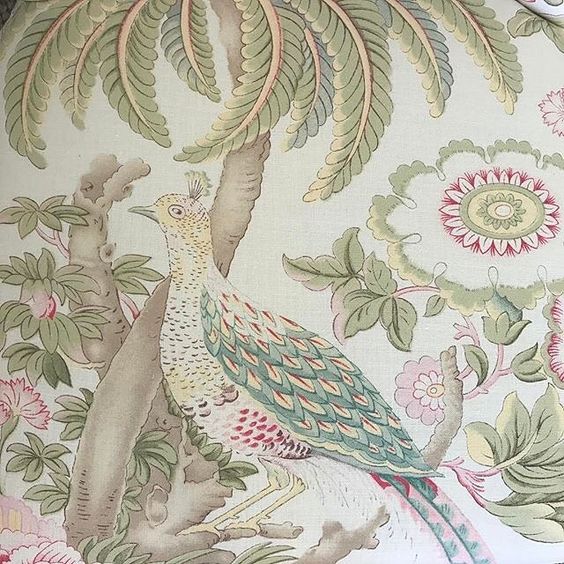

Econyl fiber is equally used in apparel and industrial applications. The most common industrial application of Econyl is carpeting, but this fiber is also used to make ropes, lines, and other types of industrial products that are otherwise made with nylon.

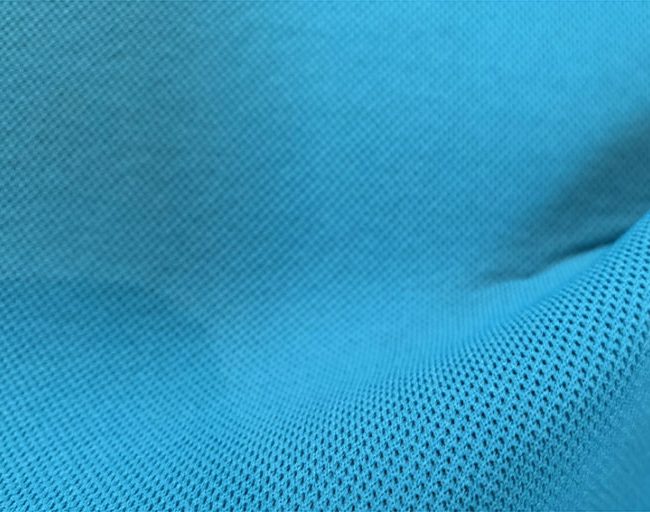

In apparel applications, Econyl is commonly used to make stockings, leggings, tights, and other form-fitting lower body garments. Econyl has recently gained some traction in the mass media due to this fabric’s increasing prominence in swimwear for both men and women. Many fashionable apparel brands that cater to young people are now offering swimwear made from Econyl to capitalize on the environmental sentiments of the younger generation.

Other apparel applications of Econyl include various types of sportswear. For instance, running shorts, cycling wear, and other form-fitting types of sportswear are commonly made with this elastic fabric.

Where Is Econyl Fabric Produced?

Aquafil has not disclosed where it currently produces Econyl fabric. This company has a variety of locations in Italy and beyond, and it’s possible that Econyl is produced at any number of these facilities.

It’s clear, however, that one of Aquafil’s facilities was opened specifically to produce Econyl fabric. This company’s Ljubljana, Slovenia Econyl Plant opened in 2011, and while current data are not available, it’s safe to assume that Aquafil continues to produce Econyl at this facility.

Aquafil also has facilities in Rayong in Thailand, Varallo Pombia in Italy, Cartersville in Georgia, and Jiaxing in China. Since Econyl is now one of this company’s most popular products, it would be safe to assume that Econyl production has expanded to one or more of these additional locations.

How Much Does Econyl Fabric Cost?

Current pricing information on Econyl is not available. This material is only available in bulk from Aquafil, which makes acquiring pricing data difficult. However, Aquafil CEO Giulio Bonazzi has this to say about the importance of pricing to Econyl’s overall success:

“Cost is a very important part. I could tell you very nice stories, but I believe that being sustainable is not only a nice thing to do, or about making the working environment satisfactory for our workers…the first rule in being sustainable is being profitable, because if you are not profitable as a company, sooner or later you go out of business, and yes, you aren’t damaging the environment – but also you don’t exist anymore.”

According to Mr. Bonazzi, driving costs of Econyl down is essential to Aquafil’s business model. Therefore, it’s reasonable to expect that Econyl is priced similarly to nylon. Even if this sustainable fabric is more expensive than nylon at present, costs will normalize as Econyl becomes more popular.

What Different Types of Econyl Fabric Are There?

At present, Aquafil produces two types of Econyl fibers:

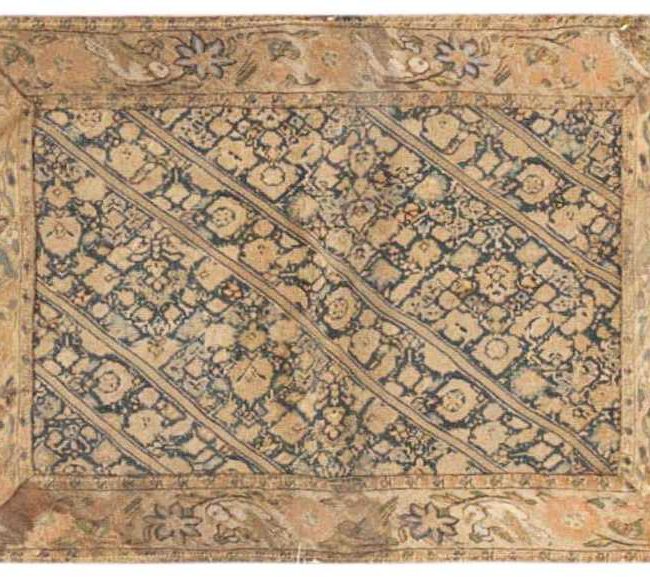

1. Econyl Carpet Fiber

While Econyl textile fiber has received a lot of acclaim in the textile industry, many environmentally conscious consumers are unaware that this fabric is also highly popular in carpeting applications. Aquafil has partnered with a variety of carpet producers around the world, and Econyl is rapidly supplanting traditional nylon as the carpet fiber of choice for many major companies.

2. Econyl Textile Fiber

The nylon 6 yarn used to make Econyl textile fiber is highly similar to the yarn used to make Aquafil’s carpet fiber, but this company’s textile fiber is softer and more fit for clothing applications. Like normal nylon, this apparel fiber can be dyed and treated with flame retardants and other important treatments.

How Does Econyl Fabric Impact the Environment?

The environmental benefits of Econyl are questionable. While it’s clear that this recycled fabric is less impactful on the environment than traditional nylon, it doesn’t solve all the environmental issues associated with this notoriously polluting fabric.

Production

First, let’s cover the environmental issues that Econyl solves. The production of this fabric involves taking waste that would have otherwise taken decades or centuries to biodegrade and making it into usable fabric. This practice saves nylon products from the landfill and the oceans, and it helps reduce the contribution of microfibers to the water supply.

Econyl also solves the issues associated with new nylon production. The main constituent of traditional nylon is hexamethylenediamine, which is a fossil fuel derivative. Environmentalists decry the detriments of fossil fuel products on the environment, but petroleum-derived fabrics, such as nylon, are just as impactful on the environment in slightly different ways.

Acquiring crude oil and coal is harmful to local ecosystems, and the refinement of fossil fuels introduces various toxic substances into the environment. Additionally, the processes used in hexamethylenediamine isolation and nylon production produce further toxic substances that are rarely disposed of effectively.

By using recycled materials, Econyl production bypasses the environmentally detrimental aspects of nylon production. Like nylon, however, Econyl is frequently dyed, and most apparel dyes are toxic and harmful to both humans and the environment.

Biodegradability

What Econyl production doesn’t solve, however, is the inherent non-biodegradability of nylon. Like all other fossil fuel-derived fabrics, Econyl is not biodegradable, and the recycled origins of this textile have no bearing on this fact. Just like nylon, discarded Econyl fabrics collect in aquatic and terrestrial ecosystems, and they contribute to the microfiber crisis that is rapidly reducing agricultural and drinking water quality around the globe.

While natural fabrics, such as cotton and wool, biodegrade within a number of years, scientists aren’t sure exactly how long it will take for synthetic fabrics to biodegrade. However, the most widely accepted estimates put the biodegradability window of synthetic fabrics at 100-1,000 years. Long after mankind stops producing synthetic fabrics, these textiles will continue to clog our ecosystems and contribute to ecological catastrophes.

Toxicity

The production of nylon is highly toxic. While it’s possible to produce nylon without harming workers, most nylon production takes place in third-world countries in which worker protection regulations are scarce, and international corporations drive wages as low as possible.

Information on the Econyl website regarding the processes used to make Econyl is vague. According to the producers of this material, a “radical regeneration and purification process” is used to transform waste vinyl into Econyl, which seems to indicate that the nylon is melted down and reformed into fibers. It is unclear whether this process produces waste products.

The Bottom Line

The producers of Econyl present their product as being part of a renewable cycle. According to Aquafil, the production of this fabric salvages nylon waste, repurposes it into nylon fiber, transforms this fiber into textile products, and then recaptures these products for recycling.

However, it is unreasonable to assume that the producers of Econyl can recapture every Econyl fabric product for repurposing. In reality, the product model for this fabric more likely resembles a process in which a small portion of the world’s nylon waste is recaptured, made into Econyl products, and then discarded.

Unless Aquafil truly recaptures every Econyl product made, this fabric is nearly as harmful to the environment as normal nylon. The only difference is that Econyl production captures a tiny amount of global nylon waste and transforms it into new fibers. Until Econyl production overtakes the production of new nylon, the overall environmental benefits of this textile will remain negligible even though they are inherently highly positive.

Econyl Fabric Certifications Available

At present, Econyl is only produced by Aquafil, which makes it impossible to comment on which certifications might be available to independent Econyl producers. However, Aquafil provides detailed information on its Econyl certifications on its official website.

Econyl is certified by DNV GL, which is an Italian governmental body that handles product certifications. Aquafil’s carpet-grade Econyl has also received Cradle to Cradle Gold certification from Desso, which is a prominent carpet producer.

Additionally, Econyl has received Standard 100 certification from OEKO-TEX. Since Econyl is a synthetic fabric, it is not eligible for organic or non-GMO certification.