What Is Hemp Fabric?

Hemp fabric is a type of textile that is made using fibers from the stalks of the Cannabis sativa plant. This plant has been recognized as a source of extraordinarily tensile and durable textile fibers for millennia, but the psychoactive qualities of Cannabis sativa have recently made it harder for farmers to produce this immensely beneficial crop.

What Is Hemp Fabric?

Over thousands of years, Cannabis sativa has been bred for two distinct purposes. On the one hand, many generations of cultivators of this plant have selectively bred it to be high in tetrahydrocannabinol (THC) and other psychoactive chemical constituents called cannabinoids. On the other hand, other cultivators have consistently bred Cannabis sativa to produce stronger and better fibers and have purposefully reduced the levels of psychoactive cannabinoids produced by their crops.

As a result, two distinct strains of Cannabis sativa have emerged. It’s a myth that hemp is made from the male Cannabis sativa plant and psychoactive marijuana is made from the female plant; in fact, the majority of hemp harvests around the world are from female plants. However, female Cannabis sativa plants that have been bred for textile purposes are very low in THC, and they do not generally have pronounced, sticky buds.

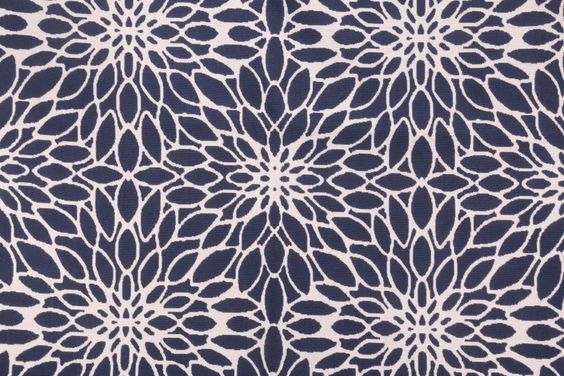

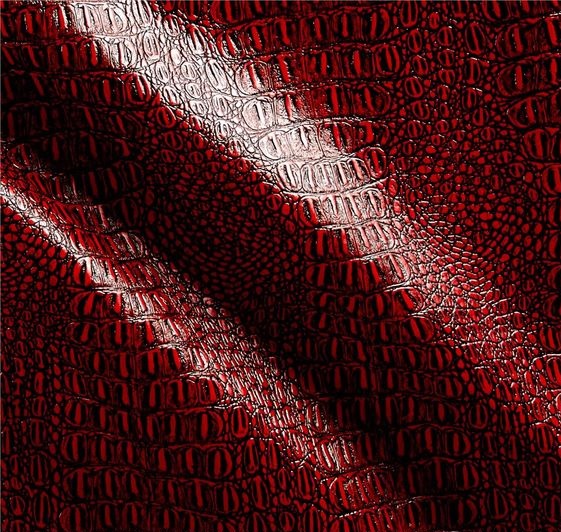

Organic hemp fabrics

The stalks of the hemp plant consist of two layers: The outer layer is formed from rope-like bast fibers, and the inner layer consists of a woody pith. Only the outer layer of the Cannabis sativa stalk is used for textile purposes; the inner, woody layer is commonly used for fuel, building materials, and animal bedding.

Once the outer layer of bast fibers is stripped from the hemp plant, it can be processed and made into rope or yarn. Hemp rope is so strong that it was once the premier choice for rigging and sails on maritime vessels, and it remains renowned as an excellent material for clothing that surpasses cotton and synthetic textiles by most metrics.

However, since much legislation around the world doesn’t make a distinction between THC-rich marijuana and hemp, which has practically no THC, the global economy doesn’t take advantage of the benefits of hemp to the degree that it could. Instead, people who don’t understand what hemp is stigmatize it as a drug. However, more and more countries are embracing the mainstream cultivation of industrial hemp, which indicates that the modern renaissance of hemp fabric is nearing its zenith.

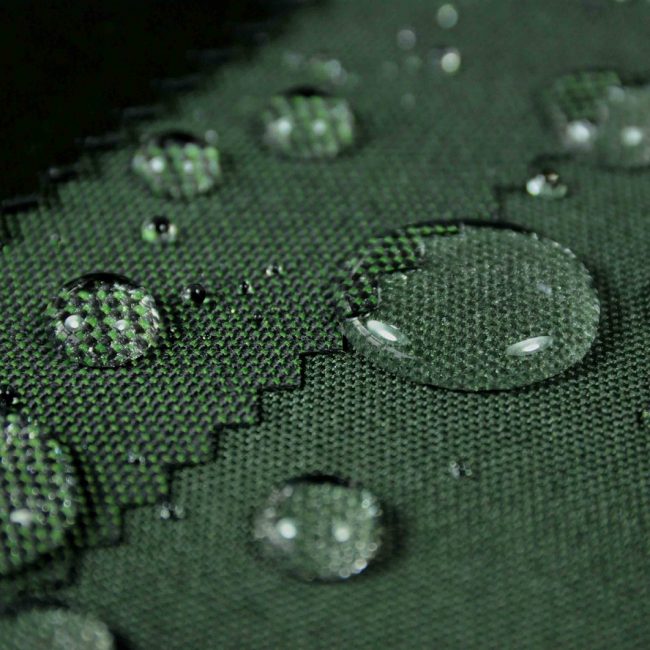

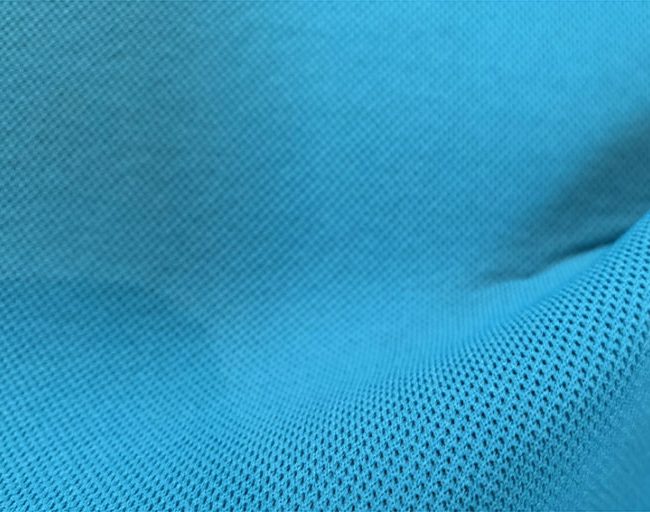

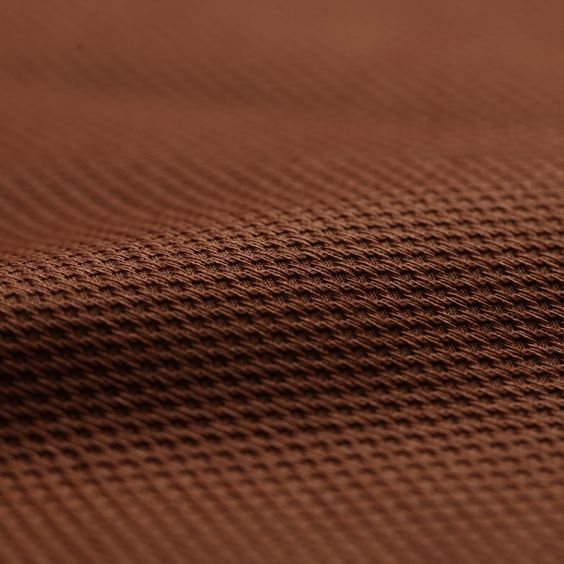

Once it is processed into fabric, hemp is has a similar texture to cotton, but it also feels somewhat like canvas. Hemp fabric is not susceptible to shrinkage, and it is highly resistant to pilling. Since fibers from this plant are long and sturdy, hemp fabric is very soft, but it is also highly durable; while a typical cotton T-shirt lasts 10 years at the most, a hemp T-shirt may last double or triple that time. Some estimates suggest that hemp fabric is three times stronger than cotton fabric.

Hemp Fabric Qualities

In addition, hemp is a lightweight fabric, which means that it is highly breathable, and it also effectively facilitates the passage of moisture from the skin to the atmosphere, so it is ideal for hot climates. It is easy to dye this type of fabric, and it is highly resistant to mold, mildew, and potentially harmful microbes.

Hemp fabric softens with each washing, and its fibers don’t degrade even after dozens of washings. Since it’s also relatively easy to produce organic hemp fabric sustainably, this textile is practically ideal for clothing.

How Is Hemp Fabric Made?

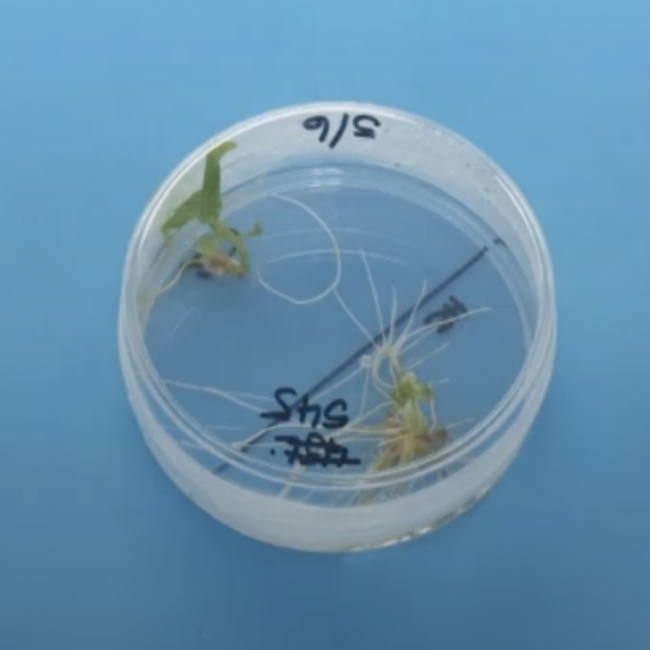

As a crop, hemp grows well in mild climates with high humidity, and Cannabis sativa plants are ready usually ready for harvest in mid-August in North America. Most plants used for hemp fabric are harvested with a special machine, and these plants are then allowed to rett in the field for 4-6 weeks, which naturally facilitates pectin removal via exposure to the elements.

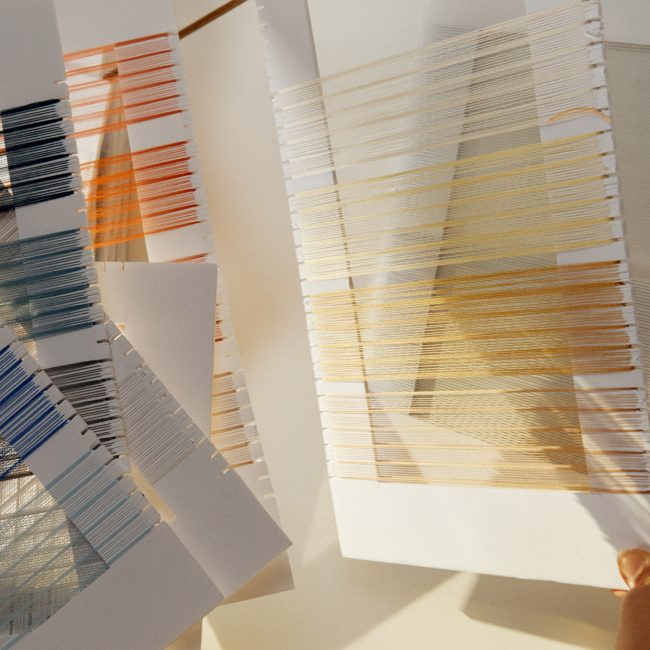

Next, these hemp stalks are made into bales like hay, and then breakers or a hammermill are used to separate the fibrous outer section of the plant from its woody core. The separated bast fibers are then carded into strands, and they are cleaned to remove impurities. Past this point, manufacturers may use pulping to produce paper products, matting to make mats and fleeces, or steam explosion to render raw hemp into a weavable fiber. Once the steam explosion process is complete, hemp is ready to be spun into yarn and woven into textiles.

At this stage, the same processes that are used to make other fabrics are used to make hemp fabric. Yarn made from this substance is woven into tight fabrics, and these fabrics may be used for a variety of consumer purposes.

How Is Hemp Fabric Used?

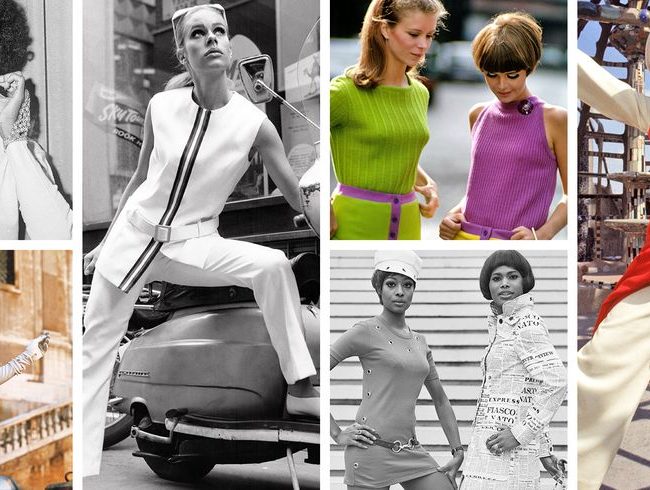

The primary use of hemp fabric is apparel. In modern history, this type of fabric was originally mainly prized as a novelty item for individuals who were enthusiastic about cannabis in general. While hemp fabric is still highly popular in the cannabis subculture, there are now plenty of people around the world who like this fabric for its beneficial qualities rather than its relationship to marijuana.

Examples of garments commonly made with hemp include dresses, skirts, pants, jackets, T-shirts, hoodies, and clothing for children. In particular, this type of fabric is highly popular for T-shirts since it is resistant to wear and tear. Most cotton T-shirts start to warp, shrink, or fall apart after comparably few washes, but hemp T-shirts retain their shape and integrity for years and years.

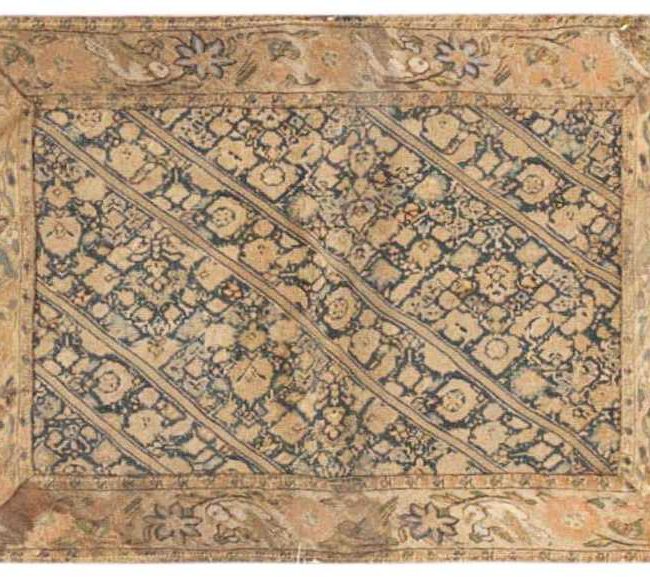

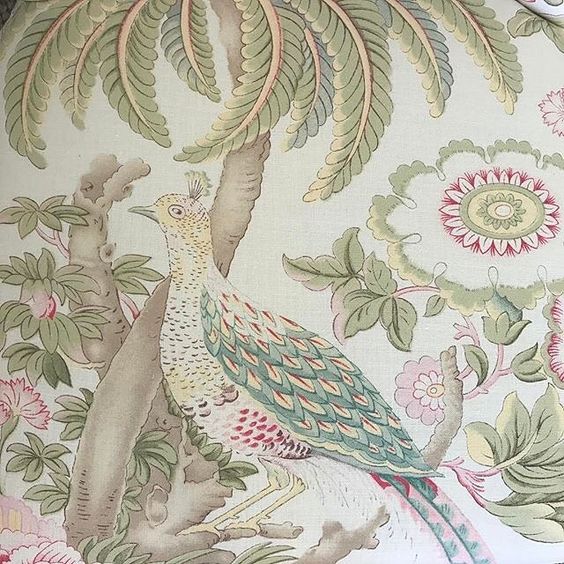

In addition, this type of fabric may also be used in a variety of hemp textiles. Again, home textiles made from this substance are more popular among marijuana enthusiasts, but using hemp fabric for tablecloths, upholstery, and dish towels is also becoming more common.

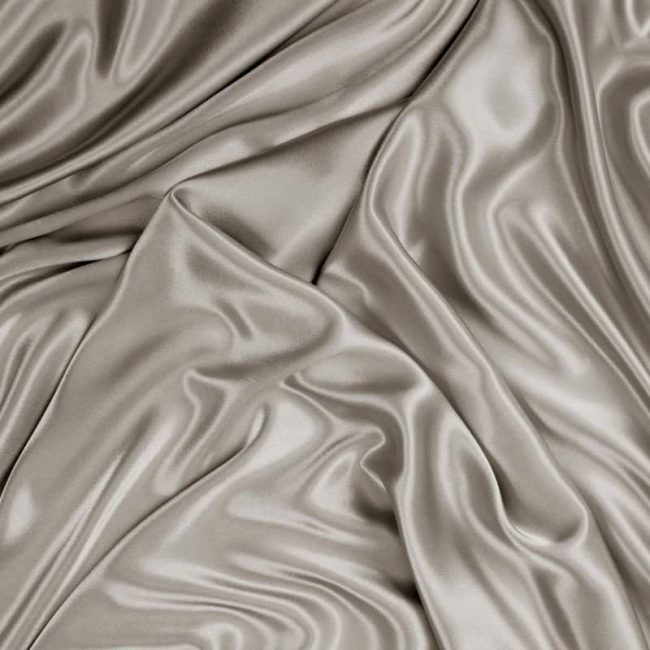

Hemp fabric is particularly popular for use in towels due to its high absorbency and durability. While some consumers may choose to use hemp bed sheets, one of the minor detractors of this fabric is that it isn’t quite as soft as cotton with high thread counts, which means it may not be incredibly comfortable to sleep with this fabric in direct contact with your skin. On the other hand, hemp fabric’s incredible durability makes it a great substance to use with blankets and duvets.

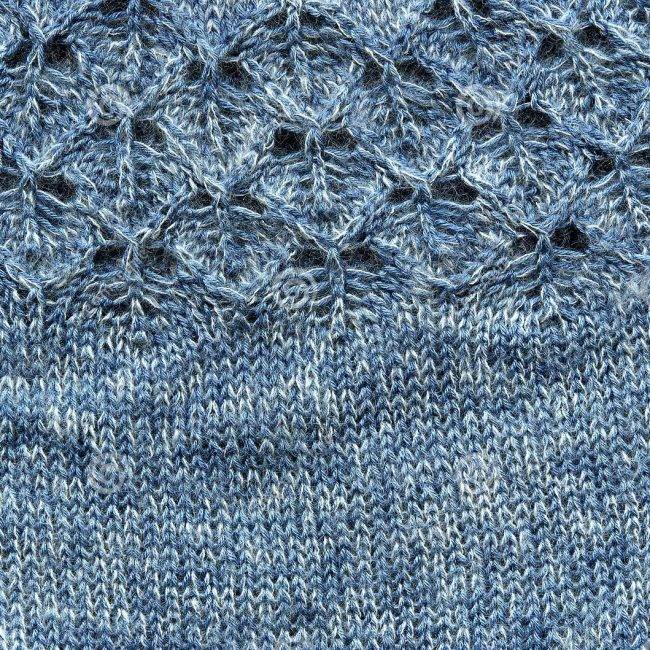

While some hemp fabric purists may choose to use textile products that are made with 100 percent hemp, it is also common to mix this type of fabric with other textiles. For instance, blends of cotton and hemp are popular, and it’s also common to find this textile blended with silk. Blending hemp with other fabrics can make this textile softer while remaining durable.

Where Is Hemp Fabric Produced?

China produces approximately 70 percent of the world’s output of this textile. However, due to lax labor laws and environmental regulations, it’s unclear whether hemp made in this country is environmentally sustainable or non-toxic. In addition, only a small portion of the hemp produced in China is made into fabric; the vast majority is made into fuel, paper, or other industrial products.

France is the next largest producer of this crop followed by Austria, Chile, and the United Kingdom. In all, over 30 countries around the world produce industrial hemp, and production of this crop in the United States is also on the upswing.

The 2014 federal farm bill permitted cultivation of industrial hemp for research purposes on the federal level in the United States, and more and more states are taking matters in their own hands and growing this crop for commercial purposes without the explicit permission of the federal government. In most cases, the states pursuing this agricultural endeavor are those that have also legalized the use of recreational marijuana.

Patagonia Men’s Iron Forge Hemp

While many changes have occurred in the arena of hemp cultivation in modern times, this plant has been an integral part of human agricultural endeavors since before the dawn of civilization. It’s believed that this crop has been cultivated for medicinal purposes for at least 10,000 years, which means that it was one of the first plants to be cultivated by human beings.

However, the development of hemp fabric did not occur until the beginning of the Iron Age. It was, on the contrary, the psychoactive and medicinal properties of this plant that caused its cultivation to spread across Europe and Asia. With the dawn of the colonial era, hemp was brought to the Americas, and it was successfully cultivated in Chile as early as the 16th century.

Notable figures in American history such as George Washington, Thomas Jefferson, and Andrew Jackson were all cultivators of hemp for industrial purposes, and it wasn’t until the 1930s that the cultivation of this crop became stigmatized in the United States. It’s possible that major producers of paper and synthetic fabrics in America feared this textile’s competitive edge and unjustly tied this fabric to the intoxicant marijuana to make its cultivation taboo.

How Much Does Hemp Fabric Cost?

Producing hemp fabric does not inherently cost more than producing cotton, but a number of market factors have driven up the cost of this fabric. For instance, cotton is produced on a much larger scale than hemp, which means that it is cheaper per volume. In addition, since hemp fabric is something of a novelty at this time, some retailers charge unreasonably inflated prices for this textile.

Handmade backpack by hemp fabric

Ironically, producing hemp fibers is actually simpler and more efficient than producing cotton, and logic dictates that this factor would drive the cost of hemp fabric lower than cotton fabric. Until legislation regarding this textile becomes more reasonable and it is accepted as a common alternative to cotton, however, this unreasonable price discrepancy will likely persist.

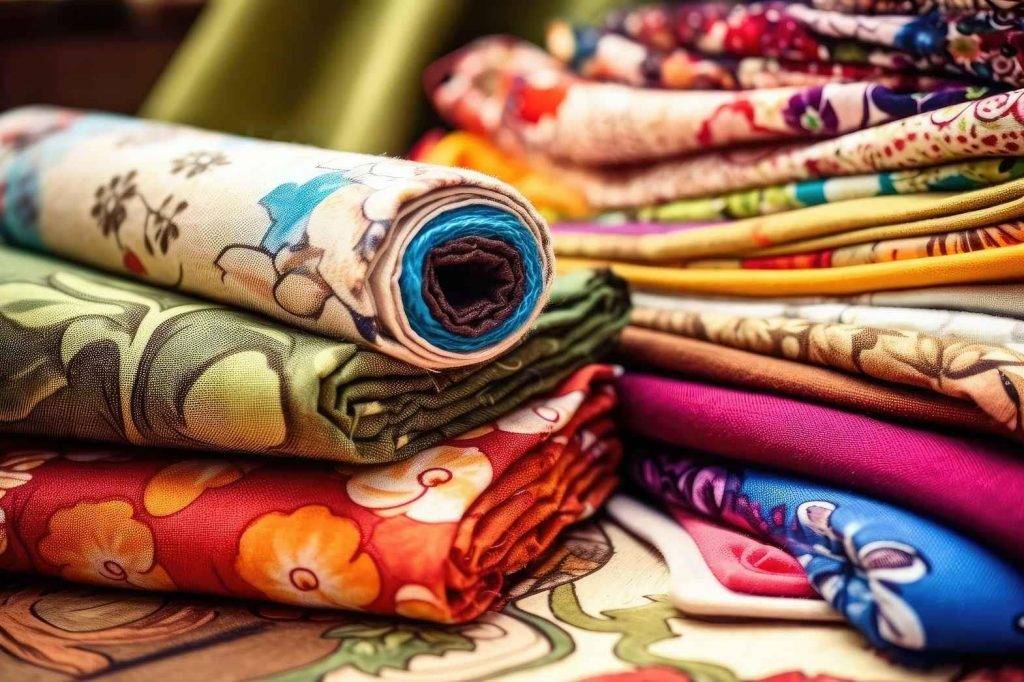

What Different Types of Hemp Fabric Are There?

Adidas Hemp Shoes

There is only one major variety of hemp fabric. While the quality, feel, and texture of this fabric may vary from manufacturer to manufacturer, the same basic process is used to make hemp fabric around the world. The resulting fabric is stronger than cotton, softer than canvas, and is durable enough to last for decades.

How Does Hemp Fabric Impact the Environment?

The production of this fabric is inherently environmentally sustainable as is evidenced by the fact that human beings have produced hemp fabric for thousands of years without incurring any major ecological calamities. However, as hemp fabric continues to be produced on a larger and larger scale, it’s unclear whether or not all producers of this fabric follow the same sustainable cultivation and manufacturing processes that are necessary to keep the production of hemp fabric ecologically sound.

In most cases, a landmark 1998 study is referenced as an authority on the subject of hemp fabric’s environmental sustainability. Researchers noted that the production of this substance requires less land than cotton, and it also releases less toxic substances into the soil and the wider ecosystem.

Hemp is also considered to be a carbon negative raw material, which means that it absorbs more carbon than it produces. Production of this crop requires very few pesticides, and it does not require any herbicides. On the other hand, it’s been indicated that producing hemp may require more nitrogen than growing cotton.

Hemp Fabric Certifications Available

Since new legislation was passed regarding industrial hemp in 2016, it’s now possible to have this crop certified as organic by the United States Department of Agriculture (USDA). It’s also possible to have this plant certified as organic in the European Union, and there are a couple of different independent organizations that certify hemp fabric once it has been fully processed.

For instance, the Global Organic Textile Standard (GOTS) only certifies fabrics that are at least 70 percent organic, and all dyes and other materials used in a fabric must also meet strict environmental standards to receive certification from GOTS. Another organization called Ecocert only certifies hemp fabric with its coveted OCS 100 logo when it contains at least 95 percent organic components.