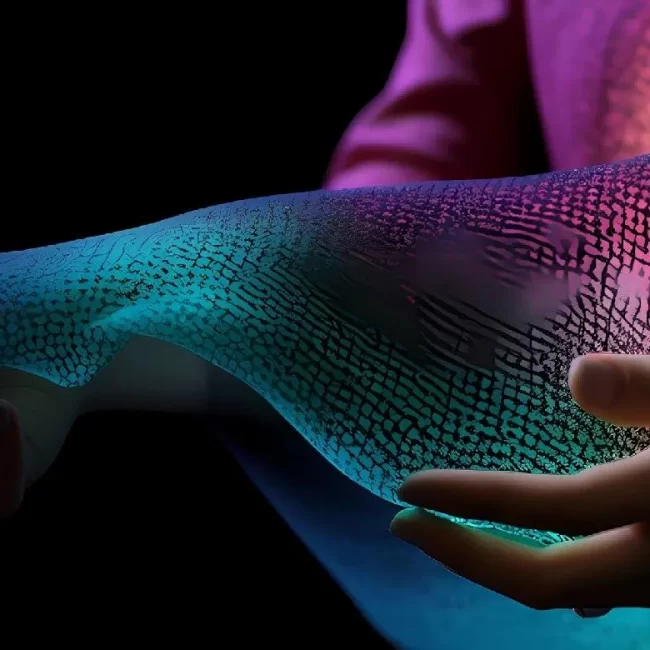

Printing Process- A Process of Decorating Textile Fabrics

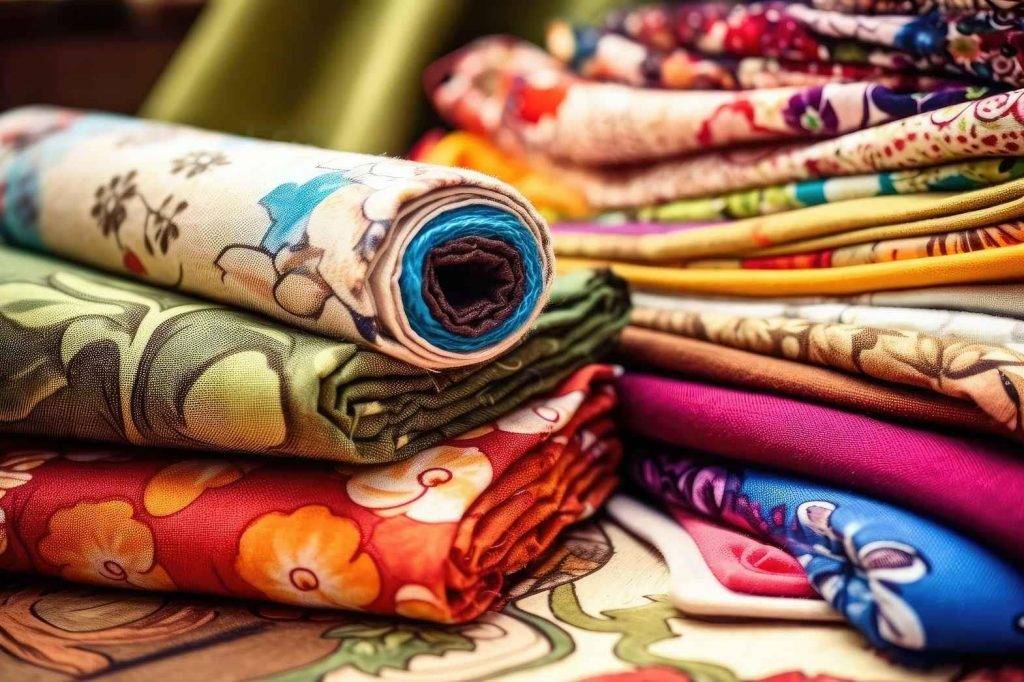

Printing is a procedure of decorating textile fabrics by applying dyes, pigments, or other materials ultimately forming patterns.

Printing is a procedure of decorating textile fabrics by applying dyes, pigments, or other materials ultimately forming patterns. Fabrics are often printed with attractive colours and various patterns by utilizing variety of techniques as well as machine types. Textile printing process is the method carried after dyeing and prior to finishing in textile manufacturing process. Among all the techniques the main methods of textile printing are block, screen, roller, and heat transfer printing. However, other methods, such as direct method, discharge, resist, and direct printing and others are also used commercially.

Following are some method of textile fabrics printing process:

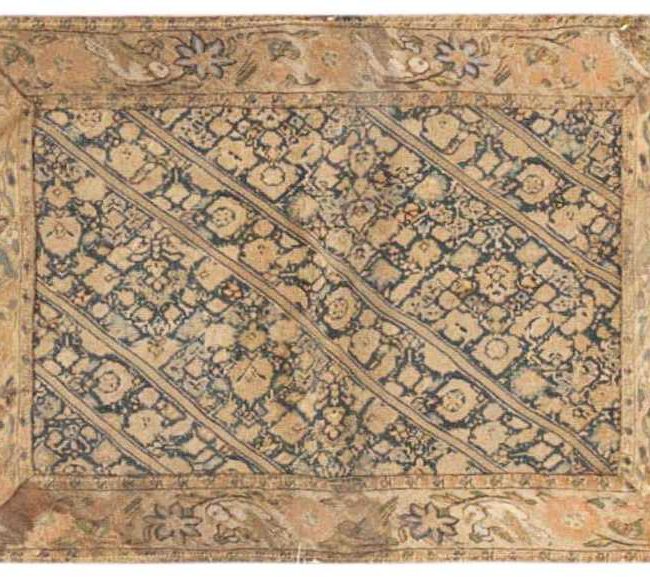

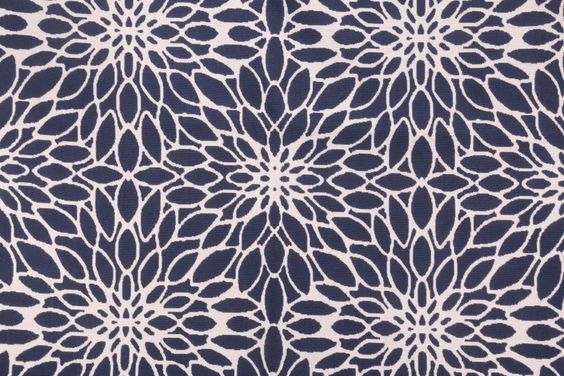

Block Printing:

Block printing process is the traditional method of printing the patterns on the fabric. The blocks used are made up of wood and the design is hand carved. This stands out as a relief against the background surface for printing. Print paste is applied on these blocks which are pressed on the fabric for printing the designs. This process is repeated with different patterns and different combination of colours until the pattern is concluded. Block printing cannot be practised in high commercial use as it is a slow process and it requires more amount of labour work.

Roller Printing:

Roller printing process technique is the method preferred for long production runs due to its rapid printing process. It is a multipurpose technique where different colours can be printed simultaneously. The roller printing equipment consist copper faced rollers into which designs are carved. Each roller rotates over the fabric by provided pressure against an iron pressure roller. A blanket/backing cloth rotates over the pressure roller under the fabric and gives a flexible support for the fabric in process being printed. A colour doctor blade in roller printing removes the paste or fibres attached to the roller. After processing of impression stage the fabric is passed to the drying and steaming stages.

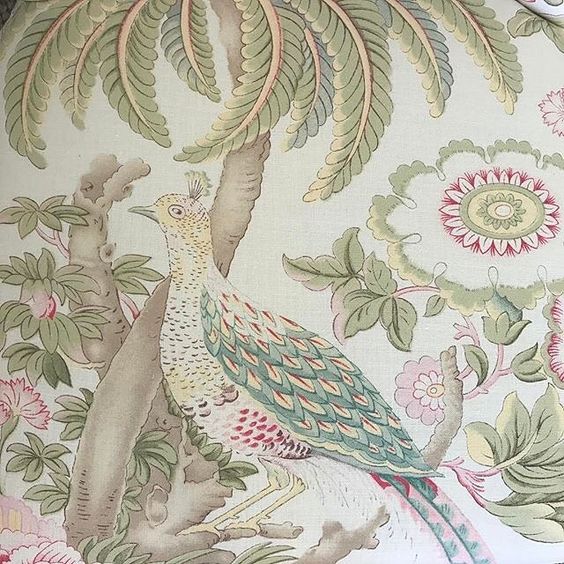

Screen Printing:

This process includes a screen i.e. a frame with a fine mesh fabric stretched over it tightly. The pattern is either in stencil form or is blocked off on the screen itself, using a screen for different colours to be printed. Dye is impelled through mesh fabric with a squeegee tool to evenly scatter the dye into the fabric in the areas below that are not blocked out. Screen printing is an expensive procedure which requires space as well as special equipment. Flat-screen printing is carried in the same way but machines are functioned at each stage and the pattern is applied to the screen digitally. On the other hand, digital printing is a suitable method for small batches of fabric.

The use of screen printing has been escalated in past few years due to it versatile quality and up gradation of rotary screen printing machines which provides high scale of output. Hefty depth of various shades can be produced by this printing.

Heat Transfer Printing:

Transfer printing technique includes the transfer of any particular design from one medium to another. The common method used is heat transfer printing, in which the design is printed firstly on a special paper by using conventional textile printing machinery. This paper is then placed in contact with the fabric and is provided heat. The dyes sublime and shifts to the fabric through the vapour.

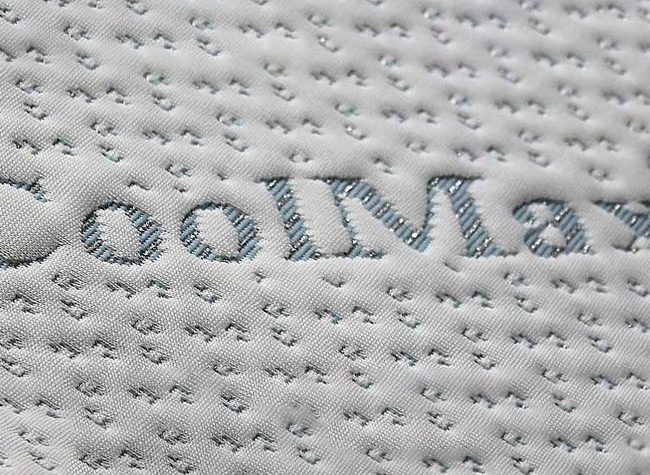

Ink-Jet Printing:

Ink-jet printing is a non-contact printing process in which droplets of colourant solution are set in motion towards a substrate and directed to desired spot. Inkjet is an emerging technology in the textile industry and has not yet been adopted for high commercial usage. The dye types most used in the ink-jet printing of textiles are vat, sulphur, fiber reactive, and naphthol dyes.

Stencilling:

Stencils are prepared from card. Here the pattern is cut out and the dye is sponged/brushed into the cut-out sections. Each stencil can be used multiple times. Today many stencils are made by usage of computerised cutting machines for high accuracy than hand-cut stencils.

Discharge Printing:

Discharge printing is held on piece-dyed fabrics. The patterns are created by removal, rather than addition of colours. Therefore, discharge printing is mostly done on dark backgrounds. When exposed to steam, the dyed fabric is printed by discharge pastes, which removes the background colour from the substrate. Colours might be added to this discharge paste to create different coloured discharge sections.

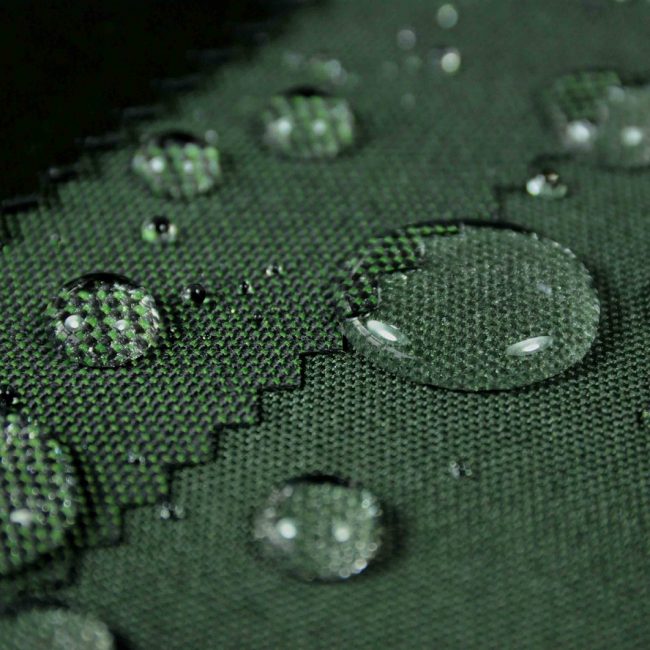

Resist Printing:

Resist printing includes multiple hands and low-volume methods in which the pattern is applied by obstructing colour from penetrating areas during piece-dyeing. Resist printing methods includes batik, tie-dyeing, screen printing, and stencil printing.

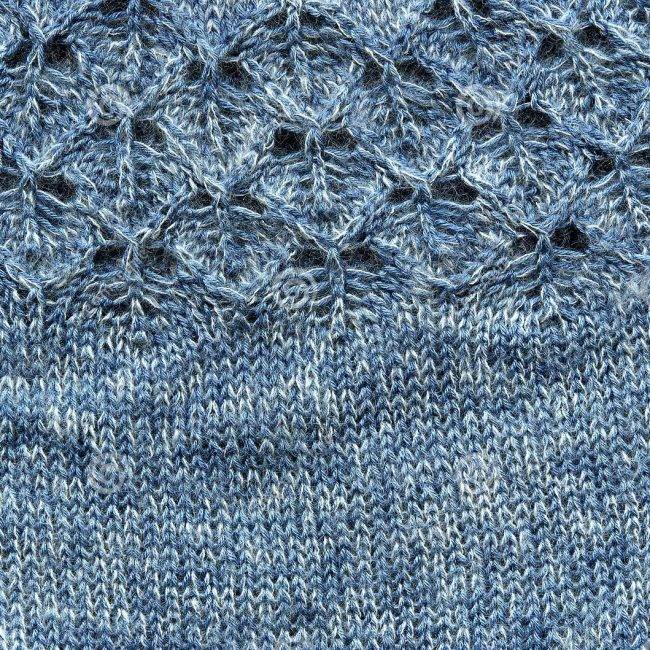

Wrap Printing:

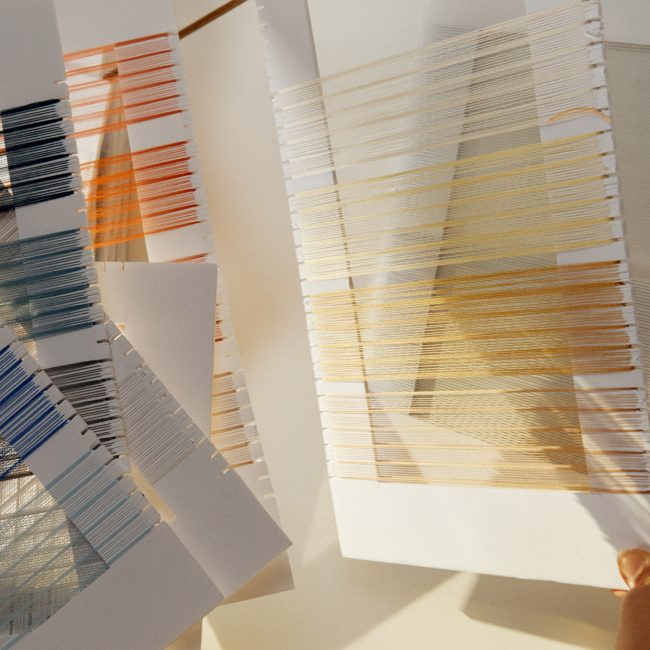

This printing includes printing of a design on warp yarns sheet before weaving. The filling is either of white colour or any neutral colour along with a gray effect produced in the areas of the design.

Direct Printing:

Direct-printing includes a large cylindrical roller which picks up the fabric, and smaller rollers consisting colours are connected with the cloth. The smaller rollers are carved with design and the rollers reflect the number of different colours. Every smaller roller is supplied with colour by a furnisher roller which rotates in colour trough, picks up the colour and uploads it on the specific applicator roller. Doctor blades scrape performs colour off to the applicator roller as a result only the engraved portions carry colour to specific cloth. The fabric is backed with a rubber quality blanket at the time of printing which allots a solid surface to the print. A layer of gray cloth is used between the cloth and rubber blanket to soak the excess ink.

Burn Out Printing:

Burn out printing is a method of printing to get a raised design on a sheer ground. The respective design is applied on fabric woven of threads pairs of various fibers with a special chemical. One of the fibers is then destroyed chemical action. Burn-out printing is often functioned on velvet.

Engraved Roller Printing:

Engraved roller printing is a method carried in textile mills for huge print runs. Here the metal rollers are engraved with a specific pattern and dye reservoirs carry the application of colour as required. As a part of screen printing a roller is required for each colour, this method results as expensive one for short runs of fabric. On the other hand, it could be cost-effective for large print runs as bundles of metres can be printed per minute easily.

All the printing operations include 70-80% of pigment usage. Textiles can also be printed by not providing any special pre treatment except woollen cloths as they are chlorinated prior to printing. Tops (parallel wool fibres) and printed in stripes are utilized for mixed effects. Printed warps generate shadowy effects.